Embarking on the journey of selecting Cloud ERP for small process manufacturing operations can feel like navigating a complex maze. For small businesses in sectors like food and beverage, pharmaceuticals, chemicals, or cosmetics, the right Enterprise Resource Planning (ERP) system isn’t just a luxury; it’s a fundamental tool for growth, efficiency, and compliance. Moving from manual processes or disparate systems to an integrated cloud-based solution offers a transformative leap, but it requires careful consideration to ensure the chosen system truly fits the unique demands of process manufacturing.

This comprehensive guide will walk you through the essential steps and critical factors involved in selecting Cloud ERP for small process manufacturing operations. We’ll delve into what makes process manufacturing distinct, why cloud solutions are particularly beneficial for smaller businesses, and how to identify a system that will not only meet your current needs but also scale with your future aspirations. Get ready to streamline your production, enhance quality control, and gain unparalleled insights into your entire operation.

Understanding the Unique Demands of Small Process Manufacturing

Small process manufacturing operations, unlike their discrete manufacturing counterparts, deal with formulas, recipes, batches, and variable yields rather than Bill of Materials (BOMs) and assembly lines. This fundamental difference means that generic ERP systems often fall short. Your ingredients aren’t simply assembled; they undergo chemical or physical transformations, leading to specific challenges in inventory management, quality control, and production scheduling.

Consider a small artisanal bakery or a boutique chemical producer. Their processes involve precise mixing, temperature control, and often, shelf-life management. Tracking ingredients from receipt through multiple transformation steps to the final product, while maintaining strict quality standards and adhering to regulatory guidelines, requires a highly specialized approach. Without a system designed for these nuances, managing waste, ensuring consistency, and achieving profitability becomes an uphill battle.

Why Cloud ERP is a Game-Changer for Small Businesses

For small businesses, the allure of cloud-based ERP solutions is multifaceted, making them an ideal choice for selecting Cloud ERP for small process manufacturing operations. Unlike traditional on-premise systems that demand significant upfront capital investment in hardware, software licenses, and dedicated IT staff, cloud ERP operates on a subscription model. This shifts expenses from CapEx to OpEx, significantly reducing the initial financial burden and making advanced technology accessible even to companies with tighter budgets.

Beyond cost, cloud ERP offers unparalleled flexibility and accessibility. Your team can access critical data and functionalities from anywhere, at any time, using just an internet connection. This is particularly beneficial for small teams who might be juggling multiple roles, or for businesses with distributed operations. Updates and maintenance are handled by the vendor, freeing up your limited internal resources to focus on core business activities rather than IT infrastructure management, ensuring your system is always up-to-date and secure.

The Core Benefits of Embracing a Cloud-Based Manufacturing ERP

Selecting Cloud ERP for small process manufacturing operations brings a host of advantages that directly impact your bottom line and operational efficiency. One of the most significant benefits is enhanced visibility across your entire supply chain. From raw material procurement to finished goods distribution, a cloud ERP system provides a single source of truth, eliminating data silos and giving you real-time insights into inventory levels, production progress, and order fulfillment.

This improved visibility translates into better decision-making, reduced waste, and optimized resource allocation. Imagine knowing precisely how much of a specific ingredient you have on hand, or predicting when a batch will be complete, enabling you to coordinate shipping more effectively. Furthermore, cloud ERP solutions often offer robust reporting and analytics capabilities, allowing you to identify trends, pinpoint inefficiencies, and forecast demand with greater accuracy, all crucial for the agility required in process manufacturing.

Essential Features for Process Manufacturing: Beyond Basic ERP

When you’re selecting Cloud ERP for small process manufacturing operations, it’s crucial to look beyond generic ERP functionalities and focus on features specifically tailored to your industry. This includes robust recipe and formula management, which allows for precise control over ingredient quantities, versions, and scaling. The ability to manage co-products and by-products, common in process manufacturing, is also vital, as is detailed batch and lot tracking for complete traceability from raw material to final product.

Quality control modules are non-negotiable, supporting in-process checks, lab testing integration, and non-conformance management. Regulatory compliance features, such as audit trails and detailed reporting for agencies like the FDA (for food/pharma) or environmental bodies, are also critical. Without these specialized functionalities, you’ll find yourself trying to force a square peg into a round hole, leading to workarounds and inefficiencies that negate the very purpose of an ERP system.

Prioritizing Scalability and Flexibility in Your ERP Solution

For growing small process manufacturing businesses, the chosen ERP system must offer inherent scalability and flexibility. Your needs today may differ significantly from your needs in two, five, or ten years. An effective cloud ERP solution should be able to accommodate increased production volumes, additional product lines, new compliance requirements, and expanding geographical reach without requiring a complete overhaul or substantial reinvestment.

When selecting Cloud ERP for small process manufacturing operations, inquire about the system’s ability to easily add users, modules, or integrations as your business evolves. Can it handle multiple production sites if you expand? Does it support international operations if you venture into new markets? A flexible system minimizes disruption during periods of growth, allowing you to focus on capitalizing on new opportunities rather than wrestling with technology limitations.

Understanding the True Cost of Cloud ERP: TCO vs. Subscription Fees

While the subscription model of cloud ERP offers clear upfront cost advantages, it’s important for small businesses to understand the Total Cost of Ownership (TCO) when selecting Cloud ERP for small process manufacturing operations. This goes beyond the monthly or annual subscription fees and includes implementation costs (setup, configuration, data migration), training expenses, potential customization costs, and ongoing support fees.

Request a detailed breakdown of all potential costs from vendors. Factor in the time your internal team will spend during implementation and ongoing management, as time is a valuable resource for small businesses. A thorough understanding of TCO will help you create a realistic budget and avoid unexpected expenses down the line, ensuring that your investment delivers the expected return without financial surprises.

Seamless Integration: Connecting Your Ecosystem

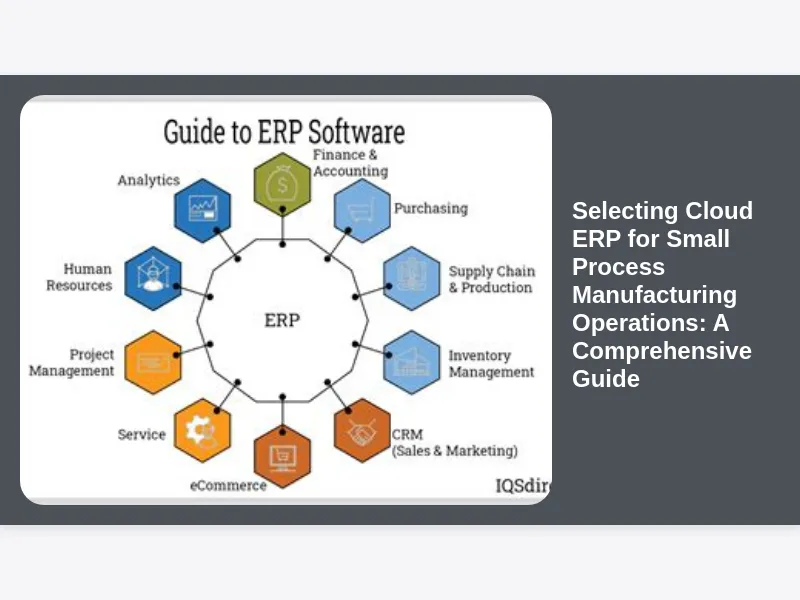

Modern manufacturing operations rarely rely on a single software solution. When selecting Cloud ERP for small process manufacturing operations, the ability to seamlessly integrate with other critical business systems is paramount. This might include your Customer Relationship Management (CRM) system for sales and customer data, your Manufacturing Execution System (MES) for detailed shop floor control, or specialized Supply Chain Management (SCM) tools for logistics and warehousing.

Poor integration leads to data silos, manual data entry, and errors, undermining the very efficiency an ERP aims to provide. Inquire about the vendor’s API capabilities, pre-built connectors, and their experience with integrating common third-party applications. A well-integrated system ensures a smooth flow of information across your entire business ecosystem, enhancing operational efficiency and providing a holistic view of your operations.

Data Security and Regulatory Compliance in the Cloud

For process manufacturing, especially in highly regulated industries like food, pharmaceuticals, or chemicals, data security and regulatory compliance are non-negotiable. When selecting Cloud ERP for small process manufacturing operations, you are entrusting your critical business data to a third-party vendor. Therefore, thoroughly vetting their security protocols and compliance certifications is essential.

Ask vendors about their data encryption methods, disaster recovery plans, data backup procedures, and physical security measures for their data centers. Ensure they comply with relevant industry standards (e.g., ISO 27001) and geographical data privacy regulations (e.g., GDPR, CCPA). For industries like pharma, inquire about features that support GxP compliance, audit trails, and electronic signatures. A robust cloud ERP system provides enterprise-grade security and helps you maintain compliance, mitigating significant business risks.

User Experience and Adoption: Ensuring Your Team Embraces the Change

Even the most feature-rich ERP system is worthless if your team finds it difficult to use or resists adoption. When selecting Cloud ERP for small process manufacturing operations, prioritize a system with an intuitive user interface and a positive user experience. Small teams often have members wearing multiple hats, and they need a system that is easy to learn and navigate, minimizing the learning curve and maximizing productivity.

Request extensive demos and, if possible, hands-on trials for key users across different departments (production, quality, finance, sales). Observe how easily they grasp the system’s functionalities. Consider the vendor’s training programs and ongoing support. A system that is well-designed and supported ensures higher user adoption rates, which is critical for realizing the full benefits of your ERP investment and achieving a smooth transition.

Vendor Reputation and Long-Term Partnership Potential

Selecting Cloud ERP for small process manufacturing operations is not just about choosing software; it’s about forming a long-term partnership with a vendor. Your chosen ERP provider will become an integral part of your business infrastructure. Therefore, thorough due diligence on their reputation, financial stability, and commitment to customer success is paramount.

Look for vendors with a proven track record in the process manufacturing sector and positive customer testimonials, particularly from businesses of similar size and industry. Inquire about their product roadmap and how they plan to evolve the software to meet future industry demands. A reliable and responsive vendor will provide excellent support, regular updates, and a commitment to helping your business thrive, fostering a partnership that extends far beyond the initial implementation.

The Implementation Journey: What to Expect and Plan For

The implementation phase is critical for the success of selecting Cloud ERP for small process manufacturing operations. It’s not just a technical process; it’s a business transformation project. Small businesses often underestimate the time and resources required for successful implementation, leading to delays and frustration. A well-defined implementation plan, clear communication, and dedicated internal resources are key.

Typically, implementation involves data migration from old systems, configuration of the ERP to match your specific workflows, user training, and rigorous testing. Phased rollouts, where modules are implemented incrementally, can often be less disruptive for small businesses than a ‘big bang’ approach. Discuss the vendor’s implementation methodology, their project management support, and the expected timeline. Realistic expectations and thorough preparation will pave the way for a smoother transition.

Customization vs. Configuration: Striking the Right Balance

A common dilemma when selecting Cloud ERP for small process manufacturing operations is the need to balance unique business processes with the benefits of standard software. While most cloud ERPs offer extensive configuration options to adapt to your workflows without altering the core code, some businesses may feel the need for deep customization. However, extensive customization can lead to higher costs, more complex upgrades, and reduced flexibility.

For small businesses, it’s generally advisable to prioritize configuration over customization. This means adapting your processes to best fit the ERP’s capabilities where possible, rather than forcing the ERP to precisely mirror your current (and potentially inefficient) legacy processes. Discuss with vendors the extent of their configuration capabilities and whether they can accommodate your essential unique requirements without resorting to costly custom development. The goal is to optimize, not just replicate.

Embracing Mobile Accessibility for On-the-Go Management

In today’s fast-paced business environment, flexibility is key. When selecting Cloud ERP for small process manufacturing operations, consider the importance of mobile accessibility. For owners, managers, or sales teams who are frequently on the go, the ability to access critical ERP data and perform essential tasks from a smartphone or tablet can be a significant advantage.

Imagine checking inventory levels from a trade show, approving purchase orders while visiting a supplier, or reviewing production metrics from the shop floor without being tied to a desktop computer. Mobile-friendly interfaces or dedicated mobile apps extend the reach of your ERP, empowering your team to be more productive and responsive, ultimately contributing to more agile and efficient operations.

Future-Proofing Your Investment: AI, IoT, and Analytics

The technological landscape is constantly evolving, and your ERP system should be able to evolve with it. When selecting Cloud ERP for small process manufacturing operations, consider how the system is positioned for future innovation. Does the vendor have a clear roadmap for incorporating emerging technologies like Artificial Intelligence (AI), Internet of Things (IoT), and advanced analytics?

While small businesses might not immediately implement complex AI-driven forecasting or IoT sensor integration, knowing that the platform is capable of supporting these advancements in the future provides long-term value. This future-proofing ensures that your ERP investment remains relevant and continues to provide competitive advantages as your business grows and technology advances. It safeguards your ability to adopt cutting-edge tools when the time is right.

Common Pitfalls to Avoid in ERP Selection

Even with careful planning, mistakes can happen. When selecting Cloud ERP for small process manufacturing operations, be aware of common pitfalls that can derail your project. One major pitfall is insufficient needs analysis; failing to clearly define your current pain points and future requirements can lead to choosing a system that doesn’t truly fit. Another is underestimating the resources (time, money, personnel) required for implementation and ongoing management.

Over-customization, as discussed, can also be a costly mistake. Neglecting change management and user adoption is another frequent error; if your team isn’t on board, even the best system will fail. Finally, ignoring vendor support and reputation can lead to frustrating experiences post-implementation. By being aware of these common traps, you can proactively avoid them and increase your chances of a successful ERP implementation.

Steps to Take Before Making Your Final Selection

Before finalizing your decision when selecting Cloud ERP for small process manufacturing operations, embark on a structured selection process. Start with a thorough internal needs assessment, involving key stakeholders from all relevant departments. Document your current processes, identify bottlenecks, and define your ideal future state. This detailed analysis will form the basis of your requirements.

Next, conduct market research to identify potential vendors. Issue a Request for Information (RFI) or Request for Proposal (RFP) to short-listed vendors, clearly outlining your specific requirements, budget, and timeline. Insist on detailed demonstrations that are tailored to your unique process manufacturing scenarios, not just generic presentations. Finally, check references, speak to current customers, and, if possible, visit an existing customer site to see the system in action.

Building Your Business Case for Cloud ERP Investment

Justifying the investment in selecting Cloud ERP for small process manufacturing operations often requires a compelling business case. For small businesses, demonstrating a clear Return on Investment (ROI) is crucial. Quantify the current costs associated with your manual processes or outdated systems, such as labor inefficiencies, inventory write-offs, compliance fines, or lost sales due to poor visibility.

Project the tangible benefits of the new system: reduced operational costs, improved inventory turns, higher production yields, better quality control leading to fewer recalls, and enhanced customer satisfaction. Include intangible benefits like improved decision-making, greater agility, and a stronger competitive position. A well-articulated business case will secure internal buy-in and help you move forward with confidence.

Strategies for a Successful Cloud ERP Implementation

A successful implementation of your chosen Cloud ERP for small process manufacturing operations hinges on several key strategies. First, assemble a dedicated project team with representatives from all departments that will use the system, ensuring diverse perspectives and ownership. Appoint a strong project manager, either internal or external, to oversee the process and maintain timelines.

Second, prioritize data quality. “Garbage in, garbage out” applies perfectly to ERP. Clean and accurate master data (products, recipes, customers, vendors) is fundamental. Third, invest adequately in user training. Hands-on training, customized to your specific workflows, will empower your team and accelerate adoption. Finally, plan for extensive testing. Conduct user acceptance testing (UAT) in a sandbox environment, simulating real-world scenarios to catch issues before going live.

Post-Implementation Optimization and Continuous Improvement

The journey doesn’t end after go-live when selecting Cloud ERP for small process manufacturing operations. Post-implementation is a critical phase for optimization and continuous improvement. Immediately after launch, monitor system performance closely, gather user feedback, and address any immediate issues or frustrations. Schedule regular check-ins with your team to understand how they are adapting and if any processes can be further streamlined.

As your business evolves, so too should your ERP usage. Explore additional modules or functionalities that can add further value. Leverage the analytics and reporting features to identify new opportunities for efficiency gains, cost reductions, or quality improvements. The true power of a Cloud ERP lies in its ability to support ongoing operational excellence and serve as a living, evolving platform for your small process manufacturing business.

Conclusion: Empowering Your Small Process Manufacturing Business

Selecting Cloud ERP for small process manufacturing operations is a significant strategic decision that can profoundly impact your business’s efficiency, profitability, and growth trajectory. By understanding the unique demands of process manufacturing, recognizing the inherent benefits of cloud solutions, and diligently evaluating vendors against your specific needs, you can choose a system that empowers your team, streamlines your operations, and provides the agility needed to thrive in a competitive market.

While the selection and implementation process requires dedication, the long-term rewards—from enhanced traceability and quality control to improved decision-making and reduced costs—make it an invaluable investment. Embrace this journey with a clear vision, a thorough plan, and a commitment to partnership, and you’ll soon unlock the full potential of a modern, integrated Cloud ERP system tailored for your small process manufacturing success.