The Dawn of a New Era for Small Factories: Embracing Digital Transformation

In the bustling world of manufacturing, small factories are often the unsung heroes, forming the backbone of global supply chains and driving innovation with agility and specialized craftsmanship. However, these vital enterprises frequently grapple with a unique set of challenges: managing complex production processes, optimizing inventory, ensuring timely deliveries, and maintaining profitability, all while operating with limited resources and often outdated systems. The traditional methods of relying on spreadsheets, disparate software, or even manual paperwork are increasingly proving inadequate in today’s fast-paced, highly competitive market.

The global economic landscape demands not just production, but smart production. Manufacturers, irrespective of their size, are under constant pressure to do more with less, react swiftly to market shifts, and deliver consistent quality. For small factories, this pressure can feel overwhelming, pushing them to the brink of stagnation if they fail to adapt. The chasm between their operational reality and the expectations of modern commerce is widening, creating an urgent need for transformative solutions that can level the playing field.

This is precisely where the power of cloud-based Enterprise Resource Planning (ERP) systems comes into sharp focus. Cloud ERP isn’t just another software; it’s a strategic platform designed to integrate all core business functions into a single, cohesive system, accessible from anywhere, at any time. For small factories, it represents a revolutionary step towards modernizing operations, shedding the shackles of inefficiency, and unlocking unprecedented levels of productivity and growth. It’s about moving beyond simply making products to intelligently managing every facet of the manufacturing journey, from raw material procurement to final product delivery.

Unpacking Cloud-Based ERP: What It Means for Manufacturing Operations

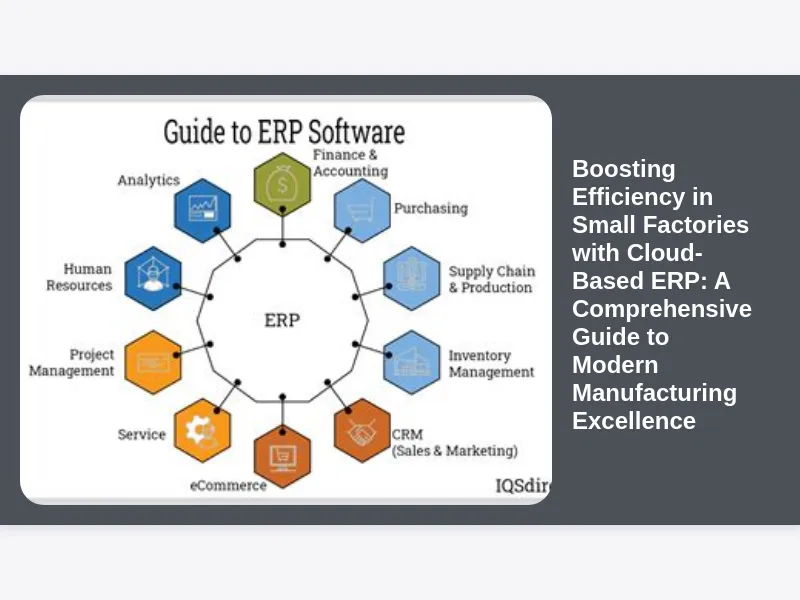

Before delving into the profound impact of cloud-based ERP, it’s crucial to understand what this technology truly entails. At its heart, an ERP system is a comprehensive suite of integrated applications designed to manage an organization’s internal and external resources, encompassing financial, manufacturing, supply chain, services, human resources, and customer relationship management. It acts as a central nervous system for your business, ensuring that information flows freely and accurately across departments.

The “cloud-based” distinction is what truly sets it apart from traditional, on-premise ERP solutions. Instead of installing and maintaining software on your own servers, cloud ERP solutions are hosted on the internet and delivered as a service (SaaS – Software as a Service). This means the software, its infrastructure, and all your data are managed by a third-party vendor in secure data centers, accessible to your factory through a web browser or mobile application. This shift from owning software to subscribing to a service carries profound implications for cost, accessibility, and scalability.

This model fundamentally alters the IT footprint of a small factory. Gone are the days of needing a dedicated IT team to manage servers, perform backups, and handle system updates. The cloud vendor takes on these responsibilities, allowing small manufacturers to focus on their core competencies: designing, producing, and delivering high-quality goods. It democratizes access to sophisticated enterprise-level technology that was once the exclusive domain of large corporations, making it an indispensable tool for Boosting Efficiency in Small Factories with Cloud-Based ERP.

The Unique Challenges Facing Small Manufacturers Today

Small factories, while agile, often face disproportionately large challenges. Their limited capital and human resources mean that every investment and every operational decision carries significant weight. Unlike their larger counterparts, they rarely have the luxury of extensive departments dedicated to logistics, inventory control, or IT infrastructure, meaning individual employees often wear multiple hats, leading to potential bottlenecks and increased risk of error.

One of the most pressing issues is often a lack of real-time visibility across operations. Production schedules might be tracked on whiteboards, inventory levels in spreadsheets that are rarely up-to-date, and customer orders manually processed. This fragmented approach leads to inefficient resource allocation, delayed decision-making, and an inability to accurately forecast demand or identify production bottlenecks before they become critical. The inability to see the entire operational picture at any given moment creates a reactive rather than proactive environment.

Furthermore, small factories are increasingly pressured by compliance requirements, fluctuating material costs, and the need to meet tighter delivery windows demanded by larger customers. Without an integrated system, responding to these external pressures can be a Herculean task, often requiring significant manual effort and leading to higher operational costs. These inherent difficulties make the case for a comprehensive, integrated solution like cloud-based ERP not just compelling, but essential for sustained competitiveness and growth.

The Imperative for Digital Transformation in the Manufacturing Sector

Digital transformation is no longer a buzzword; it’s a survival strategy for manufacturers of all sizes. The global manufacturing landscape is evolving at an unprecedented pace, driven by technological advancements like artificial intelligence, the Internet of Things (IoT), and advanced analytics. Factories that fail to adopt these innovations risk being left behind, unable to compete on cost, quality, or speed with their more digitally mature rivals.

For small factories, embracing digital transformation means strategically leveraging technology to fundamentally change how they operate and deliver value. It’s about more than just automating existing processes; it’s about rethinking entire workflows, breaking down silos between departments, and fostering a culture of data-driven decision-making. This transformation is not an overnight event but a continuous journey that requires commitment and the right technological partners.

Cloud-based ERP systems serve as a cornerstone of this digital transformation journey for small manufacturers. They provide the foundational platform upon which other advanced technologies can be integrated, enabling a holistic approach to modernization. By providing a unified view of all operations and automating routine tasks, cloud ERP frees up valuable human capital to focus on innovation, problem-solving, and strategic growth, thereby Boosting Efficiency in Small Factories with Cloud-Based ERP and preparing them for the future of manufacturing.

Boosting Efficiency in Small Factories with Cloud-Based ERP: The Core Promise

At its core, the promise of cloud-based ERP for small factories revolves around a singular, powerful objective: radical efficiency improvements. This isn’t just about saving a few minutes here and there; it’s about fundamentally reshaping how work gets done, eliminating waste, optimizing resource utilization, and accelerating every aspect of the production cycle. The integrated nature of cloud ERP ensures that every department works with the same, accurate, real-time data, thus eradicating the inefficiencies born from fragmented information and miscommunication.

Consider the typical manufacturing workflow: from initial sales order to final shipment. Without an integrated system, each stage often involves manual data entry, hand-offs between departments, and the potential for errors. Sales might promise a delivery date that production can’t meet, inventory might run out unexpectedly, or accounting might struggle to reconcile costs. Cloud ERP stitches these disparate processes together, creating a seamless, automated flow of information and tasks.

This integration means that as soon as a sales order is entered, inventory levels are checked, a production order is generated, materials are allocated, and an estimated completion date is calculated—all automatically. This level of automation and real-time visibility dramatically reduces lead times, minimizes human error, and ensures that resources—be they raw materials, machinery, or personnel—are used to their maximum potential. The result is a leaner, more agile, and significantly more efficient manufacturing operation, directly contributing to higher output and improved profitability.

Streamlining Inventory Management with Cloud ERP Solutions

Inventory management is often a make-or-break area for small factories. Holding too much inventory ties up valuable capital and increases carrying costs, while holding too little risks stockouts, production delays, and missed delivery deadlines. Traditional methods of tracking inventory, often manual or semi-automated, are prone to inaccuracies, leading to these very problems. Cloud-based ERP provides a sophisticated yet accessible solution, transforming this critical function from a liability into a strategic advantage.

A robust cloud ERP system offers real-time visibility into inventory levels across all locations, from raw materials to work-in-progress and finished goods. This means factory managers can instantly see what they have, where it is, and when it will be consumed or replenished. The system can track every movement, from receipt of goods to their issue for production, ensuring complete traceability and accountability. This precision helps prevent costly discrepancies and allows for more accurate inventory valuation.

Beyond simple tracking, cloud ERP enables advanced inventory optimization techniques. It can incorporate historical demand data, sales forecasts, and lead times to calculate optimal reorder points and quantities, often automatically generating purchase orders when stock levels hit predefined thresholds. Some systems even integrate with supplier portals, facilitating seamless communication and accelerating procurement cycles. This level of control and automation not only minimizes stockouts and overstocking but also significantly reduces the administrative burden associated with manual inventory management, directly contributing to Boosting Efficiency in Small Factories with Cloud-Based ERP.

Optimizing Production Planning and Scheduling for SMEs

For small and medium-sized enterprises (SMEs) in manufacturing, efficient production planning and scheduling are paramount to meeting customer demands and maximizing throughput. Without a clear, centralized plan, production can quickly devolve into chaos, characterized by missed deadlines, machine downtime, and inefficient resource allocation. Cloud-based ERP systems bring order and intelligence to this complex process, allowing small factories to plan and execute production with unprecedented precision.

Cloud ERP integrates sales orders, inventory levels, and available capacity (machines, labor, tools) to create optimal production schedules. It can perform detailed material requirements planning (MRP) to ensure that all necessary components are available precisely when needed, preventing costly delays. The system can also factor in machine maintenance schedules, labor availability, and even specific skill sets required for certain operations, creating a realistic and achievable production plan.

Furthermore, these systems often include advanced scheduling capabilities, allowing for dynamic adjustments as circumstances change. If a machine breaks down, an urgent order comes in, or material delivery is delayed, the ERP can quickly re-sequence jobs, identify the impact on other orders, and suggest alternative courses of action. This flexibility is invaluable for small factories that need to remain agile in a dynamic market. By providing a clear roadmap for production and the tools to adapt quickly, cloud ERP ensures that every moment on the factory floor is productive, significantly contributing to Boosting Efficiency in Small Factories with Cloud-Based ERP and driving higher output.

Enhancing Financial Visibility and Control for Manufacturers

Financial management is the lifeblood of any business, and small factories are no exception. Understanding profitability, managing cash flow, and ensuring compliance are critical for long-term survival and growth. However, manual accounting processes or disconnected financial software often lead to delays, errors, and a lack of real-time insight into the factory’s financial health. Cloud-based ERP integrates all financial transactions directly with operational data, offering unparalleled visibility and control.

From accounts payable and receivable to general ledger and cost accounting, a cloud ERP system automates many routine financial tasks, reducing the administrative burden and freeing up accounting staff for more strategic activities. Every purchase order, sales invoice, labor hour, and material consumption is automatically recorded and reflected in the financial ledgers. This seamless integration eliminates the need for manual data entry between systems, drastically reducing the chances of error and ensuring financial data accuracy.

Moreover, cloud ERP provides real-time financial reporting and analysis tools. Factory owners and managers can access up-to-the-minute dashboards showing key performance indicators (KPIs) like revenue, expenses, profit margins per product line, and cash flow. This immediate access to accurate financial data empowers informed decision-making, allowing factories to identify areas of profitability or concern instantly. Better financial control leads to better resource allocation, smarter pricing strategies, and ultimately, greater financial stability and growth, playing a crucial role in Boosting Efficiency in Small Factories with Cloud-Based ERP.

Improving Supply Chain Collaboration and Customer Satisfaction

In today’s interconnected world, a factory’s success often hinges on the strength of its supply chain. Small manufacturers rely heavily on a network of suppliers for raw materials and components, and on distributors or direct channels to reach their customers. Inefficient communication and lack of transparency within this network can lead to costly delays, quality issues, and ultimately, dissatisfied customers. Cloud-based ERP systems are designed to foster greater collaboration and dramatically improve the entire supply chain experience.

By providing a single source of truth for all operational data, cloud ERP facilitates seamless information sharing with both upstream suppliers and downstream customers. For suppliers, this can mean providing accurate forecasts, automated purchase orders, and real-time updates on material consumption, leading to more reliable deliveries and stronger relationships. Some cloud ERPs even offer supplier portals where vendors can view their orders, update shipment statuses, and communicate directly.

For customers, the benefits are even more profound. Cloud ERP integrates customer order management with production and inventory, providing accurate lead times and realistic delivery promises. If a customer inquires about their order status, a factory employee can instantly access real-time information on its progress through the production line, its packaging status, and its shipment details. This transparency builds trust and confidence, leading to higher customer satisfaction and repeat business. By streamlining communication and providing end-to-end visibility, cloud ERP ensures that the entire supply chain operates like a well-oiled machine, directly contributing to Boosting Efficiency in Small Factories with Cloud-Based ERP.

The Agility and Scalability Advantage of Cloud Platforms

One of the most compelling arguments for small factories to adopt cloud-based ERP lies in its inherent agility and scalability. Traditional on-premise ERP systems require significant upfront investment in hardware, software licenses, and IT infrastructure. Any expansion or upgrade means more capital expenditure and often a complex, time-consuming implementation process. For small businesses with fluctuating needs and limited budgets, this model can be prohibitive and stifling.

Cloud ERP fundamentally changes this paradigm. As a subscription-based service, it eliminates large upfront capital outlays, replacing them with predictable monthly or annual operational expenses. This makes sophisticated ERP technology accessible even to the smallest manufacturers. More importantly, cloud platforms are designed to scale effortlessly. As your factory grows, adds new product lines, or expands its workforce, you can easily add more users, modules, or storage capacity with minimal disruption, often with just a few clicks.

Conversely, if market conditions dictate a temporary reduction in scale, you can often adjust your subscription accordingly, avoiding idle assets. This flexibility allows small factories to respond rapidly to market changes, new opportunities, or economic fluctuations without being constrained by their IT infrastructure. The agility to adapt and the ability to grow without significant technological hurdles are critical competitive advantages in modern manufacturing, making cloud ERP an indispensable tool for Boosting Efficiency in Small Factories with Cloud-Based ERP and ensuring long-term resilience.

Demystifying Cloud ERP Implementation for Small Businesses

The thought of implementing an ERP system can be daunting for any business, and for small factories with limited IT staff, it might even seem insurmountable. Traditional ERP implementations were notorious for being complex, lengthy, and budget-intensive projects. However, cloud-based ERP solutions have significantly simplified this process, making it more accessible and less intimidating for small manufacturers. The cloud model inherently reduces many of the technical burdens.

Firstly, since the software is hosted by the vendor, there’s no need for small factories to purchase and configure servers or databases. The infrastructure is already in place. This eliminates a major hurdle and speeds up the initial setup phase. Secondly, many cloud ERP providers offer industry-specific templates and pre-configured modules that can be quickly adapted to a factory’s unique processes, rather than building everything from scratch. This “out-of-the-box” functionality significantly shortens deployment times.

While successful implementation still requires careful planning, data migration, and user training, the process is generally much smoother with cloud solutions. Vendors often provide dedicated support and project management, guiding the factory through each step. Focusing on a phased approach, perhaps starting with critical modules like inventory and production planning, can also make the transition more manageable. By breaking down the complexity, cloud ERP demystifies implementation, allowing small factories to realize the benefits of Boosting Efficiency in Small Factories with Cloud-Based ERP faster and with less stress.

Overcoming Common Challenges in ERP Adoption for SMEs

Despite the clear benefits, adopting any new technology, especially an ERP system, comes with its own set of challenges. For small and medium-sized enterprises (SMEs), these hurdles can seem particularly pronounced. One of the most common challenges is resistance to change from employees who are accustomed to old ways of working. Fear of the unknown, discomfort with new software, or simply a perceived increase in workload can lead to reluctance and hinder successful adoption.

Another significant challenge is data migration. Moving historical data from old spreadsheets, disparate systems, or even physical records into the new ERP system requires careful planning, cleaning, and validation. Incorrect or incomplete data migration can severely impact the effectiveness of the new system and erode user confidence. Ensuring data integrity from the outset is paramount for the ERP to deliver accurate insights and drive efficient operations.

Furthermore, selecting the right cloud ERP solution is a challenge in itself, given the multitude of vendors and features available. Small factories must carefully assess their specific needs, budget, and future growth plans to choose a system that truly aligns with their operational requirements. Overcoming these challenges requires strong leadership, clear communication, adequate training, and a willingness to invest time and resources into the transition. With a strategic approach, these hurdles can be successfully navigated, paving the way for Boosting Efficiency in Small Factories with Cloud-Based ERP and long-term success.

Realizing Return on Investment (ROI) and Long-Term Benefits

The decision to invest in a cloud-based ERP system, like any significant business investment, must be justified by a clear return on investment (ROI). For small factories, this ROI is typically realized through a combination of tangible cost savings, increased revenue opportunities, and intangible benefits that strengthen the business foundation. Quantifying these returns helps factory owners understand the true value proposition of ERP.

Tangible benefits often include reduced operational costs through automation and process optimization. This means less manual data entry, fewer errors, decreased inventory holding costs due to better management, and optimized production schedules that minimize waste and machine downtime. Furthermore, improved cash flow management and more accurate financial reporting contribute directly to the bottom line. The ability to fulfill more orders, reduce lead times, and improve delivery reliability can also lead to increased sales and market share.

Beyond immediate financial gains, cloud ERP delivers significant long-term benefits. Enhanced data analytics provide deeper insights into business performance, enabling more strategic decision-making and continuous improvement. The agility and scalability of cloud platforms ensure that the system can evolve with the factory, supporting future growth and market shifts. Improved customer satisfaction builds brand loyalty, while a more efficient workplace can boost employee morale. These compounded benefits underscore how cloud ERP is not just an expense, but a strategic investment that fundamentally improves the factory’s competitive position and ensures the sustained Boosting Efficiency in Small Factories with Cloud-Based ERP.

Security and Data Protection in Cloud ERP Environments

A common concern among businesses considering cloud adoption, particularly small factories dealing with sensitive production data and intellectual property, is the security and privacy of their information. The idea of data residing off-site, managed by a third party, can raise questions and anxieties. However, modern cloud ERP providers invest heavily in robust security measures that often surpass the capabilities of what a small factory could implement and maintain on its own.

Reputable cloud ERP vendors employ multi-layered security protocols, including advanced encryption for data in transit and at rest, stringent access controls, regular security audits, and continuous monitoring for threats. Their data centers are typically fortified facilities with physical security measures, redundant power supplies, and sophisticated firewalls. Furthermore, they usually adhere to industry-specific compliance standards and certifications, providing an additional layer of assurance regarding data protection and regulatory adherence.

Moreover, cloud ERP providers perform regular data backups and disaster recovery planning, ensuring business continuity even in the face of unforeseen events. For a small factory, replicating this level of security and resilience internally would be financially prohibitive. By entrusting their data to a specialized cloud provider, small manufacturers can benefit from enterprise-grade security without the associated complexity or cost, allowing them to focus on production with confidence that their critical information is protected. This robust security framework is integral to the successful implementation of Boosting Efficiency in Small Factories with Cloud-Based ERP.

Future-Proofing Your Factory: AI, IoT, and Cloud ERP Synergy

The manufacturing sector is on the cusp of another technological revolution, driven by advancements in Artificial Intelligence (AI) and the Internet of Things (IoT). For small factories looking to remain competitive and innovative, integrating these cutting-edge technologies is crucial. Cloud-based ERP systems are uniquely positioned to serve as the foundational platform for leveraging AI and IoT, effectively future-proofing the factory’s operations.

IoT devices, embedded in machinery and equipment, can collect vast amounts of real-time data on performance, temperature, vibration, and energy consumption. When this data is fed into a cloud ERP system, it can be analyzed using AI algorithms to identify patterns, predict potential equipment failures before they occur (predictive maintenance), and optimize machine utilization. This proactive approach significantly reduces unplanned downtime, extends asset life, and improves overall equipment effectiveness (OEE).

Furthermore, AI can enhance various ERP functions, from demand forecasting and production scheduling to quality control and supply chain optimization. AI-powered analytics can uncover hidden insights from operational data, helping factories make smarter decisions about everything from raw material procurement to optimal pricing strategies. The scalability and flexibility of cloud ERP make it the ideal environment for these data-intensive, intelligent applications, enabling small factories to harness the power of AI and IoT without requiring massive on-premise infrastructure investments. This synergy is key to continuously Boosting Efficiency in Small Factories with Cloud-Based ERP and staying ahead in the market.

Choosing the Right Cloud ERP Vendor: Key Considerations for SMEs

Selecting the right cloud ERP vendor is a critical decision that will significantly impact the success of a small factory’s digital transformation journey. With numerous options available, ranging from industry giants to niche providers, small manufacturers must approach this choice with careful consideration, aligning their specific needs with the vendor’s offerings. It’s not just about features, but also about partnership and support.

Firstly, evaluate the vendor’s industry expertise. Does the ERP solution have specific modules or functionalities tailored for manufacturing, and more specifically, for your type of manufacturing (e.g., discrete, process, batch)? A system designed with manufacturing best practices in mind will require less customization and be quicker to implement. Look for case studies or testimonials from similar small factories that have successfully implemented their solution.

Secondly, consider scalability and flexibility. Will the system grow with your factory? Can it easily integrate with other tools you might use (e.g., CAD software, e-commerce platforms)? Understand the pricing model clearly, including subscription costs, implementation fees, and potential costs for future upgrades or additional modules. Finally, assess the vendor’s support and training offerings. A strong support team and comprehensive training resources are invaluable during and after implementation, ensuring your team can effectively leverage the system for Boosting Efficiency in Small Factories with Cloud-Based ERP. Don’t hesitate to ask for detailed demos and trials.

Success Stories: Real-World Impact on Small Manufacturers

The theoretical benefits of cloud-based ERP become truly compelling when viewed through the lens of real-world success stories. Small factories across various manufacturing sectors are already reaping significant rewards by adopting these modern systems, transforming their operations and achieving remarkable growth. These narratives serve as powerful examples of how Boosting Efficiency in Small Factories with Cloud-Based ERP is not just a concept, but a tangible reality.

Consider a small custom machinery manufacturer that struggled with long lead times and inconsistent delivery dates due to fragmented spreadsheets and manual production scheduling. After implementing a cloud ERP, they gained real-time visibility into every order’s progress, optimized their production floor, and reduced lead times by 25%. This not only improved customer satisfaction but also allowed them to take on more projects, leading to a substantial increase in revenue. The integrated inventory management also cut down on material waste, directly impacting their profitability.

Another example involves a small food processing plant facing challenges with stringent regulatory compliance and traceability. By adopting a cloud ERP solution tailored for process manufacturing, they were able to track every ingredient from farm to fork, automate compliance reporting, and significantly reduce the time spent on audits. This enhanced traceability not only ensured regulatory adherence but also built greater trust with their customers and protected their brand reputation. These stories highlight that regardless of the specific industry or challenge, cloud ERP provides the tools for significant operational and strategic improvements.

The Human Element: Training and Change Management for ERP Adoption

While technology is the enabler, the ultimate success of any cloud ERP implementation hinges on the people who use it: the factory’s employees. The “human element” is often the most overlooked yet critical component of ERP adoption. Even the most sophisticated system will fail to deliver its promised benefits if employees are not adequately trained, supported, and engaged in the transition process. Effective change management is paramount to ensure smooth adoption and maximum utilization.

Initial training sessions are vital, but ongoing support and resources are equally important. Training should be role-specific, showing each employee how the new system directly impacts their daily tasks and makes their jobs easier or more efficient. This helps to demystify the technology and build confidence. Creating super-users or internal champions who can assist their colleagues and answer questions can also foster a supportive learning environment.

Furthermore, communicating the “why” behind the change is crucial. Employees need to understand how the new ERP system will benefit the factory as a whole, improve their individual roles, and contribute to job security and growth. Addressing concerns, listening to feedback, and involving employees in the process from the early stages can transform resistance into enthusiasm. By investing in comprehensive training and thoughtful change management, small factories can ensure their team fully embraces the new system, thereby maximizing the potential for Boosting Efficiency in Small Factories with Cloud-Based ERP and achieving sustainable success.

The Path Forward: Embracing Continuous Improvement with Cloud ERP

Adopting a cloud-based ERP system is not a one-time project; it’s the beginning of a journey towards continuous improvement and operational excellence for small factories. The dynamic nature of cloud platforms means that systems are regularly updated with new features, security enhancements, and industry best practices. This ensures that your factory always has access to the latest technological advancements without the need for disruptive, expensive upgrades.

Beyond the software itself, a robust cloud ERP provides the data and insights necessary to drive ongoing optimization. By consistently analyzing performance metrics, identifying bottlenecks, and tracking key performance indicators, factory managers can make informed decisions to refine processes, introduce new efficiencies, and adapt to evolving market demands. This data-driven approach transforms the factory from a reactive entity into a proactive, intelligent operation capable of constant evolution.

Embracing cloud ERP positions small factories to thrive in an increasingly complex and competitive global marketplace. It empowers them to punch above their weight, leveraging technology once reserved for large enterprises to achieve unprecedented levels of efficiency, agility, and profitability. By committing to this digital transformation, small manufacturers are not just Boosting Efficiency in Small Factories with Cloud-Based ERP; they are building resilient, future-ready businesses poised for sustained growth and innovation.

Conclusion: A Blueprint for Manufacturing Excellence

In an era defined by rapid technological advancement and fierce global competition, the imperative for small factories to innovate and optimize their operations has never been clearer. Relying on outdated systems and fragmented processes is no longer a viable strategy for survival, let alone growth. The future of manufacturing, even for the smallest players, is intrinsically linked to intelligent, integrated, and accessible technology.

Cloud-based ERP systems offer precisely this solution: a comprehensive, scalable, and cost-effective platform that addresses the unique challenges faced by small manufacturers. From streamlining inventory and optimizing production to enhancing financial control and fostering supply chain collaboration, cloud ERP touches every facet of the business, unifying disparate functions into a cohesive, efficient whole. It empowers these vital enterprises to not only compete but to excel against larger rivals, delivering quality products faster and more reliably.

The journey to Boosting Efficiency in Small Factories with Cloud-Based ERP is a strategic investment in the factory’s future. It’s about more than just software; it’s about embracing a new paradigm of operational excellence, data-driven decision-making, and continuous improvement. By making this transformative leap, small manufacturers can unlock their full potential, ensuring their enduring relevance and prosperity in the dynamic landscape of modern industry. The time to modernize is now, and cloud ERP provides the blueprint for that success.