Introduction: Navigating the Complexities of Modern Manufacturing

In today’s rapidly evolving global economy, small manufacturing businesses face an unprecedented array of challenges. From fluctuating supply chains and rising material costs to intense competition and the constant pressure to innovate, staying competitive requires more than just a great product. It demands operational excellence, financial agility, and the ability to adapt at lightning speed. Many small manufacturers often find themselves bogged down by disparate systems, manual processes, and a lack of real-time visibility into their operations, hindering their ability to truly grow.

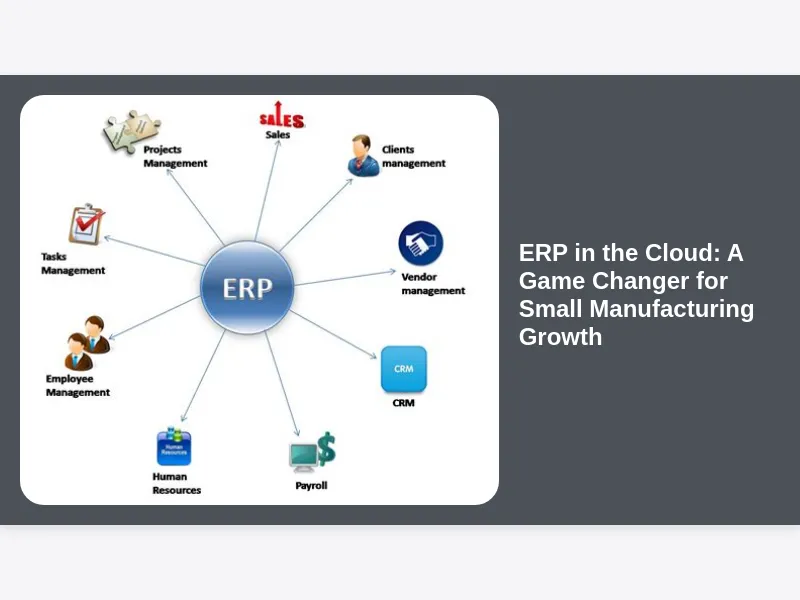

For years, Enterprise Resource Planning (ERP) systems have been the backbone of large corporations, providing integrated software solutions to manage all core business processes. However, the traditional, on-premise ERP model often came with a hefty price tag, complex implementation cycles, and a significant IT overhead that was simply out of reach for most small to medium-sized manufacturing enterprises (SMEs). This left a critical gap, forcing smaller players to cobble together siloed software or rely on spreadsheets, preventing them from leveraging the kind of integrated data and process optimization that their larger counterparts enjoyed.

But a fundamental shift has occurred. The advent of cloud computing has democratized access to powerful enterprise-grade software, making sophisticated ERP systems not only accessible but also incredibly beneficial for small manufacturers. ERP in the Cloud: A Game Changer for Small Manufacturing Growth is no longer a futuristic concept; it’s a present reality that offers a pathway to unprecedented efficiency, scalability, and competitive advantage. This article will delve deep into how cloud-based ERP solutions are transforming the landscape for small manufacturing businesses, empowering them to overcome traditional hurdles and embark on significant growth trajectories. We’ll explore the tangible benefits, address common concerns, and provide insights into leveraging this transformative technology.

The Cloud ERP Revolution: Redefining Enterprise Software for SMBs

For many years, the term “ERP” conjured images of massive, expensive software installations, requiring dedicated IT teams and months, if not years, of customization and deployment. This model was inherently incompatible with the lean operations and limited resources characteristic of small manufacturing businesses. Traditional ERP was a fortress, often impenetrable for those without substantial capital and technical infrastructure. The promise of integrated data and streamlined processes remained tantalizingly out of reach, a luxury reserved for the industrial giants.

However, the proliferation of cloud computing has dismantled these barriers, ushering in a new era of accessibility and flexibility. Cloud ERP fundamentally changes the ownership and delivery model of enterprise software. Instead of purchasing and maintaining software on your own servers, you subscribe to a service hosted by a third-party provider over the internet. This shift from capital expenditure to operational expenditure, from in-house management to managed services, has profoundly impacted the viability of ERP for smaller organizations. It’s about moving from owning and maintaining a complex engine to simply paying for the fuel and enjoying the ride.

This paradigm shift isn’t just about cost; it’s about agility, maintenance, and focus. Small manufacturers can now tap into the same sophisticated functionalities that were once the exclusive domain of large enterprises, without the associated IT burden. The cloud provider handles the infrastructure, software updates, security patches, and backups, allowing the manufacturing business to concentrate on what it does best: producing goods. It’s an operational liberation that allows small teams to punch above their weight, leveraging technology previously deemed too complex or too costly. This is precisely why ERP in the Cloud is a Game Changer for Small Manufacturing Growth, enabling them to leapfrog technological limitations and embrace digital transformation.

Unlocking Agility and Scalability: Fueling Manufacturing Business Growth

One of the most significant advantages of ERP in the Cloud for small manufacturers is its unparalleled agility and scalability. Traditional software solutions were often rigid, requiring significant upfront investment and custom development that made adapting to market changes a slow and arduous process. If a small manufacturer experienced a sudden surge in orders, or conversely, needed to scale back production, their on-premise systems could become a bottleneck, either struggling to cope with increased demand or proving to be an underutilized, expensive asset during slower periods.

Cloud ERP, by its very nature, is designed for flexibility. It operates on a subscription model, allowing businesses to easily scale their usage up or down based on current needs. Need to add more users during a peak production season? No problem, it’s typically a few clicks away. Want to integrate a new module for advanced planning? Cloud solutions often offer modularity, allowing businesses to add functionalities as they grow, rather than investing in a monolithic system all at once. This inherent elasticity means that cloud ERP acts as a dynamic foundation, capable of supporting both periods of rapid expansion and phases of consolidation, without forcing prohibitive infrastructure investments or leaving expensive hardware idle.

This inherent scalability is vital for small manufacturing growth. It removes the technological ceiling that often limits ambition. A business can start lean, with core functionalities, and gradually expand its ERP capabilities as its operational complexities and employee base grow. This “pay-as-you-grow” model minimizes risk and optimizes resource allocation, ensuring that technology investments align directly with business needs and growth phases. It truly empowers small manufacturers to think big, knowing their ERP system can evolve alongside their expanding operations, making ERP in the Cloud a Game Changer for Small Manufacturing Growth by enabling seamless, cost-effective scaling.

Cost-Effectiveness and Predictable ROI: Budget-Friendly ERP for SMBs

For small manufacturing businesses, every penny counts. The prohibitive upfront costs associated with traditional ERP – licensing fees, server hardware, installation, and extensive customization – were often insurmountable. These massive capital expenditures created a significant barrier to entry, forcing many to forgo the benefits of integrated management systems. The financial risk was simply too high for businesses operating on tighter margins and with less access to capital.

Cloud ERP dramatically alters this financial landscape. It shifts the expenditure from a large capital outlay to a more manageable operational expense. Instead of buying software, you subscribe to it, paying a monthly or annual fee. This subscription model eliminates the need for expensive servers, dedicated IT infrastructure, and the ongoing costs of power, cooling, and maintenance for on-premise hardware. Furthermore, many cloud ERP providers include software updates, security patches, and basic technical support within the subscription fee, providing predictable budgeting and reducing unexpected expenses. This transparency in costing allows small manufacturers to accurately forecast their technology spend, making financial planning much simpler.

The reduction in total cost of ownership (TCO) is profound. Small manufacturers save on initial hardware purchases, software licenses, implementation services (often streamlined for cloud), and ongoing IT maintenance. This frees up crucial capital that can be reinvested directly into core manufacturing operations, product development, or marketing initiatives. The lower entry barrier and predictable cost structure mean that the return on investment (ROI) for cloud ERP often becomes much clearer and quicker to realize, directly contributing to the financial health and growth of the small manufacturing business. It’s a strategic investment that offers clear, tangible financial advantages, solidifying ERP in the Cloud as a Game Changer for Small Manufacturing Growth.

Real-time Visibility and Data Analytics: Empowering Informed Decisions

In the fast-paced world of manufacturing, timely and accurate information is paramount. Without it, decision-making becomes reactive, based on guesswork or outdated reports. Many small manufacturers struggle with fragmented data, locked away in spreadsheets, departmental silos, or disparate legacy systems. This lack of a single source of truth means that understanding inventory levels, production bottlenecks, order statuses, or financial performance can be an arduous, time-consuming task, often leading to delays, errors, and missed opportunities.

ERP in the Cloud revolutionizes this by providing a centralized database where all critical business data resides. From sales orders and raw material inventory to production schedules and financial ledgers, every piece of information is captured and integrated in real-time. This real-time visibility is transformative. A production manager can instantly see the status of a specific job on the shop floor, a sales representative can confirm product availability for a customer, and a business owner can access up-to-the-minute financial dashboards, all from a unified platform. This immediate access to current, accurate data eliminates blind spots and fosters a proactive approach to management.

Beyond mere visibility, cloud ERP systems often come equipped with robust reporting and analytics capabilities. These tools allow small manufacturers to slice and dice their data, identify trends, predict demands, and pinpoint inefficiencies. Imagine being able to analyze production cycle times to optimize workflows, forecast inventory needs based on sales patterns, or assess the profitability of specific product lines with precision. This data-driven insight empowers small manufacturing businesses to make informed, strategic decisions, leading to optimized operations, reduced waste, and ultimately, accelerated growth. The ability to transform raw data into actionable intelligence is a core reason why ERP in the Cloud is a true Game Changer for Small Manufacturing Growth.

Streamlining Operations: Enhancing Manufacturing Efficiency

Operational efficiency is the cornerstone of profitability for any manufacturing business, and small manufacturers are no exception. The traditional approach often involves manual data entry, repetitive tasks, and disconnected departmental processes, all of which introduce errors, delays, and significant overhead. Imagine a sales order being manually re-entered into a production schedule, then again into an inventory system, and finally into an invoicing system – each step is a potential point of failure and a drain on valuable time.

Cloud ERP systems are designed to eliminate these inefficiencies by automating and integrating core manufacturing processes. From the moment a customer places an order, the system can automatically trigger inventory checks, create production orders, generate work instructions, track materials consumption, and even initiate shipping processes. This seamless flow of information and automated task execution drastically reduces manual effort, minimizes human error, and accelerates the entire order-to-cash cycle. For example, robust inventory management modules ensure optimal stock levels, reducing holding costs and preventing stockouts that could halt production.

Furthermore, cloud ERP often includes functionalities specifically tailored for manufacturing, such as production planning and scheduling, material requirements planning (MRP), and shop floor control. These tools allow small manufacturers to optimize their production runs, manage capacity effectively, and track progress against schedules in real-time. By streamlining these complex operational workflows, cloud ERP frees up valuable employee time, allowing them to focus on higher-value activities like process improvement or product innovation, rather than administrative tasks. This pervasive increase in efficiency is a direct contributor to the growth potential, making ERP in the Cloud truly a Game Changer for Small Manufacturing Growth.

Enhanced Supply Chain Management: Connecting the Ecosystem

A robust and resilient supply chain is critical for any manufacturing business, regardless of size. For small manufacturers, managing suppliers, vendors, and logistics can be particularly challenging, often relying on phone calls, emails, and disconnected spreadsheets. This lack of integrated visibility can lead to inventory imbalances, production delays due to material shortages, and difficulties in responding quickly to supply disruptions or changes in demand. The entire manufacturing process hinges on the smooth flow of goods and information throughout the supply chain.

ERP in the Cloud extends its reach beyond internal operations to encompass the entire supply chain ecosystem. By integrating with supplier portals, vendor management systems, and logistics providers, cloud ERP provides a holistic view of the material flow, from raw material procurement to finished goods delivery. This means real-time tracking of orders from suppliers, better forecasting of material needs based on production schedules, and improved communication with external partners. Imagine being able to instantly check the status of an incoming shipment or automatically generate purchase orders when inventory levels drop below a predefined threshold.

Moreover, cloud ERP can facilitate better collaboration with suppliers and customers. Through integrated communication tools and shared data dashboards, small manufacturers can improve relationships, negotiate better terms, and reduce lead times. The system can provide alerts for potential supply chain disruptions, allowing for proactive contingency planning rather than reactive firefighting. By enabling a more transparent, efficient, and responsive supply chain, cloud ERP strengthens the operational foundation of small manufacturers, reducing risk and paving the way for consistent growth. This interconnectedness is a profound benefit, cementing ERP in the Cloud as a Game Changer for Small Manufacturing Growth.

Improving Customer Satisfaction: CRM Integration and Beyond

In today’s competitive landscape, customer satisfaction is not merely a goal but a critical driver of growth and loyalty. For small manufacturers, building strong customer relationships often relies on personalized service and deep product knowledge. However, when customer data is scattered across multiple systems – sales, production, shipping, and accounting – providing a unified and consistent customer experience becomes incredibly challenging. Enquiries about order status, delivery timelines, or product specifications can lead to internal scavenger hunts, frustrating both staff and customers.

ERP in the Cloud plays a pivotal role in enhancing customer satisfaction by centralizing customer information and integrating it with core operational data. Many cloud ERP solutions offer built-in Customer Relationship Management (CRM) functionalities or seamless integrations with popular standalone CRM platforms. This means that a customer’s entire history – sales orders, invoices, support tickets, communication logs, and even specific product configurations – is accessible from a single dashboard. Imagine a customer service representative instantly knowing the exact production stage of a custom order or quickly resolving a billing inquiry with full transactional history at their fingertips.

This comprehensive view empowers small manufacturers to provide faster, more accurate, and more personalized customer service. It enables proactive communication regarding order updates, potential delays, or new product offerings. Furthermore, by linking sales data with production and inventory, businesses can make more informed promises about delivery dates and product availability, improving reliability and trustworthiness. When customers experience seamless interactions and dependable service, their loyalty strengthens, leading to repeat business and valuable referrals. This customer-centric approach, facilitated by integrated cloud ERP, is undoubtedly a core aspect of why ERP in the Cloud is a Game Changer for Small Manufacturing Growth.

Data Security and Compliance: Addressing Cloud Concerns Proactively

One of the most common concerns for businesses considering ERP in the Cloud is data security. Entrusting sensitive company information – financial records, intellectual property, customer data – to a third-party provider naturally raises questions about privacy, breaches, and compliance. For small manufacturers, who may not have dedicated cybersecurity teams, this can be a significant hurdle to adoption. It’s crucial to understand how cloud providers address these vital concerns.

Reputable cloud ERP providers invest heavily in security infrastructure and protocols that far exceed what most small manufacturers could afford or manage internally. They employ multiple layers of security, including physical security for data centers, network firewalls, intrusion detection systems, encryption for data at rest and in transit, and robust access controls. Many adhere to stringent international security standards and certifications, such as ISO 27001, SOC 1/2/3, and GDPR compliance, which demonstrates their commitment to data protection. They also perform regular security audits and vulnerability assessments to identify and mitigate potential threats proactively.

Furthermore, cloud providers typically offer comprehensive backup and disaster recovery plans, ensuring business continuity even in the event of unforeseen incidents. This level of resilience and protection is often impractical and cost-prohibitive for small manufacturers to implement on their own. While due diligence is always recommended when selecting a vendor, the reality is that major cloud ERP providers generally offer a higher level of security and compliance than what an average small business could achieve with an on-premise system. Addressing these security concerns with robust solutions allows small manufacturers to confidently embrace this transformative technology, further proving that ERP in the Cloud is a Game Changer for Small Manufacturing Growth.

Remote Accessibility and Collaboration: The Modern Workforce Enablement

The COVID-19 pandemic profoundly reshaped the way businesses operate, highlighting the critical importance of remote work capabilities and seamless collaboration across distributed teams. For many small manufacturers, reliance on on-premise systems meant that critical business functions were tied to the physical office or factory, hindering flexibility and resilience. Accessing key information or managing operations away from the main site became a significant logistical challenge, impacting productivity and responsiveness.

ERP in the Cloud inherently supports remote accessibility and enhanced collaboration. Since the software is accessed via a web browser from any internet-connected device, employees can perform their duties from anywhere – whether it’s a sales representative checking inventory from a client’s office, a production manager monitoring the shop floor from home, or an accountant managing invoices while traveling. This flexibility is invaluable for small manufacturers who may have a lean team, some of whom need to be on the road, or who might increasingly adopt hybrid work models. It empowers a more agile and geographically dispersed workforce without compromising access to critical business data.

Beyond simple access, cloud ERP fosters collaboration by providing a single, unified platform for all business processes and data. Teams can work on shared documents, track project progress, and communicate within the system, reducing reliance on email chains and disparate communication tools. Everyone operates from the same, up-to-date information, minimizing misunderstandings and improving coordination between departments, from sales and production to finance and logistics. This seamless connectivity and collaborative environment are essential for modern operational efficiency, making remote work not just possible but highly productive, solidifying ERP in the Cloud as a Game Changer for Small Manufacturing Growth.

Easing Implementation and Maintenance: Less IT Headache for Small Manufacturers

Traditionally, implementing an ERP system was a daunting undertaking, often likened to a major construction project. It involved significant upfront planning, hardware procurement, software installation, extensive customization, and months, if not years, of deployment, often requiring a dedicated team of IT specialists and consultants. For small manufacturing businesses with limited IT resources, this complexity and time commitment were often prohibitive, causing projects to stall or fail.

ERP in the Cloud simplifies the entire implementation and ongoing maintenance process dramatically. Since the software is hosted and managed by the vendor, small manufacturers avoid the burden of purchasing and maintaining server hardware, operating systems, and database software. The cloud provider handles all infrastructure management, software updates, patches, and routine maintenance tasks. This significantly reduces the need for an extensive in-house IT department, freeing up valuable resources and allowing the business to focus on its core competencies: manufacturing. Implementation, while still requiring careful planning and data migration, is often quicker and less disruptive, with many cloud solutions offering standardized configurations that accelerate deployment.

The “set it and forget it” aspect (to a reasonable degree) of cloud ERP means less IT headache and more operational stability. Small manufacturers benefit from always having access to the latest version of the software, complete with new features and security enhancements, without the need for manual upgrades. This continuous improvement, managed externally, ensures the system remains current and performs optimally, without placing a strain on internal resources. This operational ease and reduced IT burden directly contribute to business efficiency and sustainability, underscoring why ERP in the Cloud is a Game Changer for Small Manufacturing Growth.

Integrating with Emerging Technologies: Future-Proofing Manufacturing Operations

The manufacturing landscape is rapidly evolving, driven by advancements in technologies like the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), and robotics. For small manufacturers, leveraging these emerging technologies can be a significant competitive differentiator, but integrating them with outdated, on-premise legacy systems can be incredibly complex, expensive, and often impossible. This can leave them lagging behind larger, more technologically advanced competitors.

ERP in the Cloud offers a platform that is inherently designed for integration and adaptability to these new technological frontiers. Cloud-based systems often feature open APIs (Application Programming Interfaces) and robust integration frameworks, making it much easier to connect with external systems and emerging technologies. Imagine connecting IoT sensors on the shop floor directly to your cloud ERP to get real-time data on machine performance, predictive maintenance needs, or production output, automatically updating your inventory and scheduling. This seamless data flow enables truly smart manufacturing.

Furthermore, many cloud ERP providers are actively incorporating AI and ML capabilities directly into their platforms. This means small manufacturers can leverage intelligent automation for tasks like demand forecasting, quality control analysis, or even optimizing shipping routes without needing to develop these complex algorithms in-house. This future-proof architecture ensures that as new technologies emerge and become essential, your cloud ERP system can evolve and integrate with them, keeping your manufacturing operations at the cutting edge. This forward compatibility and technological readiness are why ERP in the Cloud is a profound Game Changer for Small Manufacturing Growth, enabling businesses to embrace the future of industry.

Choosing the Right Cloud ERP Partner: Key Considerations for Small Manufacturers

The decision to adopt ERP in the Cloud is a significant one for any small manufacturing business, and choosing the right partner is paramount to success. With numerous vendors offering a variety of solutions, the selection process can seem overwhelming. It’s not just about the software features, but also about the vendor’s understanding of your industry, their support capabilities, and their long-term vision. A well-chosen partner can be a true ally in your growth journey, while a poor fit can lead to frustration and wasted resources.

Firstly, assess the vendor’s industry-specific expertise. Does their cloud ERP solution have features specifically designed for discrete manufacturing, process manufacturing, or assembly operations, which align with your business model? Generic ERPs might provide some benefits, but one tailored to manufacturing will offer specialized functionalities like bill of materials management, production routing, or quality control modules that are crucial for your operations. Look for case studies or client testimonials from similar businesses within the manufacturing sector.

Secondly, consider the scalability, integration capabilities, and total cost of ownership (TCO). Will the solution scale with your projected growth without requiring a complete system overhaul? How easily does it integrate with your existing critical systems, such as CAD software, CRM, or e-commerce platforms? Get a clear understanding of all costs involved – subscription fees, implementation costs, potential customization fees, and ongoing support – to avoid hidden surprises. Finally, evaluate their customer support and training resources. A strong support team and comprehensive training materials are essential for a smooth transition and ongoing user adoption. The right choice in a cloud ERP partner is critical for unlocking the full potential of ERP in the Cloud as a Game Changer for Small Manufacturing Growth.

Overcoming Resistance to Change: A Smooth Transition to Cloud ERP

Introducing a new ERP system, particularly one that shifts operations to the cloud, can trigger apprehension and resistance within any organization, especially in established small manufacturing businesses. Employees may be comfortable with existing processes, even if they are inefficient, and the prospect of learning new software can feel daunting. Successful adoption hinges not just on the technology itself, but on effective change management and a clear communication strategy. Ignoring this human element can derail even the most technically sound implementation.

To ensure a smooth transition, start by clearly articulating the “why.” Explain to your team why ERP in the Cloud is being implemented – focusing on how it will benefit them and the business as a whole. Emphasize improved efficiency, reduced manual tasks, better data access, and the overall positive impact on the company’s growth and stability. This proactive communication helps to alleviate fears and build buy-in, transforming potential resistors into advocates. Involve key users from various departments in the selection and planning phases, giving them a sense of ownership in the process. Their insights are invaluable, and their participation will make them champions of the new system.

Provide comprehensive training tailored to different user roles, moving beyond basic functionality to demonstrate how the new system will improve their daily workflows. Ongoing support, easily accessible resources, and a designated internal champion or “super user” can help address questions and overcome initial learning curves. Celebrate small wins during the implementation process and acknowledge the efforts of your team. By strategically managing the human element and fostering a culture of adaptability, small manufacturers can navigate the transition to cloud ERP smoothly, unlocking its full potential as a Game Changer for Small Manufacturing Growth without significant internal friction.

Measuring Success: Key Performance Indicators for Cloud ERP Implementation

Implementing ERP in the Cloud is a significant investment for a small manufacturing business, and like any major strategic initiative, its success needs to be measured. Simply having the system in place isn’t enough; you need to assess its tangible impact on your operations, finances, and growth trajectory. Establishing clear Key Performance Indicators (KPIs) before, during, and after implementation is crucial for demonstrating ROI and identifying areas for further optimization. Without objective metrics, it’s difficult to truly appreciate how the cloud ERP has become a Game Changer for Small Manufacturing Growth.

Consider a blend of operational, financial, and customer-centric KPIs. Operationally, you might track metrics such as order fulfillment cycle time (from order placement to delivery), inventory accuracy rates, production lead times, machine uptime, or the number of manual data entry errors. A reduction in these figures clearly indicates improved efficiency. Financially, monitor cost reductions in IT overhead, improved cash flow through faster invoicing and collections, reductions in inventory holding costs, and overall profitability improvements. These metrics demonstrate the direct financial benefits of the new system.

From a customer perspective, track on-time delivery rates, customer satisfaction scores (if available), and resolution times for customer inquiries. Improvements here indicate a more responsive and reliable business. Additionally, internal KPIs like employee productivity per user or the reduction in time spent on administrative tasks can highlight the positive impact on your workforce. Regularly review these metrics and use them to refine your processes and ensure you are maximizing the value derived from your cloud ERP. This data-driven approach ensures that the investment in ERP in the Cloud truly translates into sustainable and measurable Small Manufacturing Growth.

The Future Landscape: What’s Next for Cloud Manufacturing?

The evolution of ERP in the Cloud is far from over; in fact, it’s just gaining momentum, continually reshaping the landscape for small manufacturing businesses. The trends indicate an even deeper integration of intelligence, automation, and connectivity, promising a future where manufacturing operations are more agile, predictive, and resilient than ever before. Understanding these forthcoming developments can help small manufacturers position themselves strategically to continue leveraging cloud ERP as a perpetual Game Changer for Small Manufacturing Growth.

One major trend is the accelerated convergence of ERP with advanced analytics, Artificial Intelligence (AI), and Machine Learning (ML). This will move beyond simple reporting to truly predictive capabilities: forecasting demand with greater accuracy, optimizing production schedules in real-time based on unexpected events, and even enabling prescriptive maintenance for machinery before breakdowns occur. Imagine your ERP system not just telling you what happened, but what will happen and what you should do about it. The integration of IoT data from the factory floor will become even more seamless, creating digital twins of physical assets for precise monitoring and simulation.

Furthermore, we’ll see a greater emphasis on sustainability and circular economy principles within cloud ERP platforms. Tools for tracking carbon footprints, managing waste reduction, and optimizing resource consumption will become standard, allowing small manufacturers to not only improve efficiency but also meet growing environmental compliance and consumer demand for eco-friendly products. The future of cloud manufacturing is one of hyper-connectivity, intelligent automation, and sustainable operations, all powered by integrated cloud ERP systems that continue to empower small manufacturers to compete and thrive on a global scale.

Is Cloud ERP Right for Your Small Manufacturing Business? A Final Consideration

After exploring the myriad benefits and practical considerations of ERP in the Cloud, the crucial question remains: is it the right fit for your small manufacturing business? While the advantages are compelling – from cost-effectiveness and scalability to real-time insights and enhanced customer satisfaction – the decision requires careful self-assessment and strategic alignment. It’s not a one-size-fits-all solution, but for many, it represents the vital next step in their journey toward sustained growth and competitiveness.

Consider your current pain points. Are you struggling with fragmented data, inefficient processes, difficulty scaling, or a lack of visibility into your operations? Are manual errors impacting your profitability or customer satisfaction? If you find yourself constantly battling these challenges, then cloud ERP offers a clear pathway to resolution. Assess your growth ambitions: do you plan to expand your product lines, enter new markets, or increase production volume significantly? A robust, scalable cloud ERP system can provide the foundational support needed to achieve these goals without being hindered by outdated technology.

Ultimately, ERP in the Cloud offers small manufacturers a powerful opportunity to level the playing field with larger competitors, embrace digital transformation, and unlock significant growth potential. It’s about moving beyond simply managing your business to truly optimizing it. By addressing the specific needs of small manufacturing, cloud ERP is proving to be a true Game Changer for Small Manufacturing Growth, enabling businesses to be more agile, intelligent, and profitable in an increasingly complex world. Take the time to evaluate your unique circumstances, engage with reputable vendors, and embark on a journey that could redefine your operational capabilities and secure your future success.

Conclusion: The Path Forward for Small Manufacturing

The journey of a small manufacturing business in the modern era is fraught with challenges, yet brimming with opportunities. For decades, sophisticated business management tools remained largely out of reach, leaving smaller players to navigate complex operational landscapes with fragmented systems and limited visibility. However, the advent and maturation of cloud computing have profoundly transformed this dynamic, offering an unprecedented pathway to efficiency, scalability, and competitive advantage. ERP in the Cloud is not just a technological upgrade; it’s a strategic imperative that is fundamentally reshaping how small manufacturers operate, empowering them to thrive in a globalized and increasingly digital marketplace.

We’ve explored how cloud ERP delivers tangible benefits, from significant cost savings and predictable expenditure to unparalleled real-time data visibility and the ability to scale operations seamlessly. It streamlines production, optimizes supply chains, enhances customer satisfaction, and liberates businesses from the burden of complex IT infrastructure. Moreover, cloud ERP platforms are inherently designed to integrate with emerging technologies, ensuring that small manufacturers remain at the forefront of innovation, ready to embrace the future of industry with AI, IoT, and advanced analytics. Addressing concerns around data security and facilitating smooth implementation, cloud solutions are making enterprise-grade management accessible and manageable for lean teams.

The message is clear: for any small manufacturing business aspiring for sustainable growth, improved profitability, and enhanced agility, embracing ERP in the Cloud is a strategic move that simply cannot be overlooked. It provides the integrated foundation needed to turn operational challenges into competitive strengths, allowing businesses to focus on what they do best – creating high-quality products. As the manufacturing landscape continues to evolve, cloud ERP will remain a pivotal enabler, solidifying its position as a true Game Changer for Small Manufacturing Growth. The time to leverage this transformative technology is now, paving the way for a more efficient, resilient, and prosperous future.

References (Example Placeholders – In a live article, these would be active links to specific reports/articles):

- [Link to a Gartner or Forrester report on Cloud ERP adoption trends in SMBs]

- [Link to an industry survey on manufacturing challenges and technology solutions]

- [Link to a Deloitte or PwC analysis on digital transformation in manufacturing]

- [Link to a reputable technology blog or news site discussing cloud security best practices]

- [Link to a case study from a cloud ERP provider featuring a successful small manufacturing implementation]