The Digital Imperative: Why Small Manufacturers Can’t Ignore Cloud ERP

In today’s fiercely competitive global market, small manufacturing businesses face an unprecedented array of challenges. From supply chain disruptions and escalating material costs to a skilled labor shortage and the constant pressure to innovate, staying afloat, let alone growing, demands more than traditional methods. For years, Enterprise Resource Planning (ERP) systems have been the backbone of large corporations, integrating diverse business functions into a single, cohesive system. However, the high costs, complex implementations, and extensive IT infrastructure required for traditional, on-premise ERP solutions often put them out of reach for smaller enterprises.

This landscape, however, is rapidly evolving. The advent of cloud computing has democratized access to powerful business tools, fundamentally shifting how businesses operate. For small manufacturers, this isn’t just an incremental improvement; it’s a paradigm shift, a true game changer. ERP in the Cloud is no longer a luxury reserved for the Fortune 500; it’s becoming an indispensable tool for achieving sustainable growth, boosting efficiency, and gaining a competitive edge, even for the most agile, independent manufacturers. It promises to transform how these businesses manage everything from raw materials to final product delivery, offering a level of visibility and control that was once unimaginable without significant capital investment.

The core of this transformation lies in its ability to centralize data, automate processes, and provide real-time insights without the heavy burden of managing complex IT systems. This article will delve deep into how ERP in the Cloud: A Game Changer for Small Manufacturing Growth is empowering these businesses, exploring its multifaceted benefits, addressing common concerns, and outlining the path to successful adoption. We’ll uncover how this technology can unlock new levels of productivity, enhance decision-making, and ultimately propel your small manufacturing business towards unprecedented success in the digital age.

Understanding the Cloud ERP Revolution: Beyond Traditional Boundaries

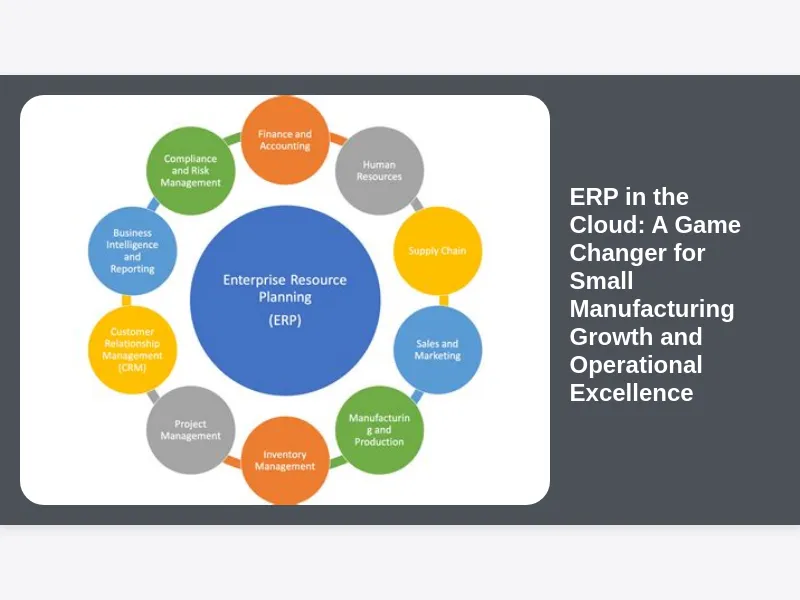

Before we explore its transformative power, it’s crucial to grasp what ERP in the Cloud truly entails and how it differs from its traditional predecessor. At its heart, ERP is a software system designed to manage and integrate all core business processes, including finance, human resources, manufacturing, supply chain, services, procurement, and more. It provides a single source of truth for all business data, replacing disparate systems and manual processes that often lead to inefficiencies and errors.

Historically, ERP systems were deployed “on-premise,” meaning the software was installed and run on servers located within a company’s own data center. This approach demanded significant upfront capital expenditure for hardware, software licenses, and the hiring of dedicated IT staff for installation, maintenance, and ongoing support. For a small manufacturer, this represented a formidable financial and operational hurdle, often making the investment simply unfeasible. The complex setup and constant need for upgrades and patches further added to the burden, diverting resources that could otherwise be used for core manufacturing activities.

Cloud ERP, by contrast, operates differently. Instead of being installed locally, the software is hosted on remote servers managed by a third-party provider and accessed over the internet, typically through a web browser. This model, often referred to as Software-as-a-Service (SaaS), means you subscribe to the service rather than purchasing and owning the software outright. The vendor handles all the infrastructure, maintenance, security, and updates, freeing your manufacturing business from the complexities of IT management. This fundamental shift in deployment and ownership is precisely what makes ERP in the Cloud such a compelling and accessible solution for small manufacturing operations aiming for significant growth.

Why Traditional ERP Fell Short for Small Manufacturing Operations

For decades, the concept of a fully integrated ERP system remained largely out of reach for small and medium-sized manufacturers. While the benefits of centralized data and streamlined processes were well understood, the practicalities of implementing and maintaining such a system presented insurmountable obstacles. These challenges were multifaceted, touching upon financial, operational, and technical aspects unique to smaller enterprises.

Firstly, the prohibitive upfront costs were often the biggest deterrent. Traditional ERP implementations required substantial investments in server hardware, networking equipment, database licenses, and the software licenses themselves, typically paid as a lump sum. For a small manufacturing business operating on tighter margins and with limited capital, allocating hundreds of thousands or even millions of dollars to an IT project was simply not viable. This massive initial outlay often meant sacrificing investments in new machinery, product development, or marketing, severely hindering growth potential.

Secondly, the operational complexity associated with on-premise ERP was a significant burden. Small manufacturers rarely have a large, dedicated IT department equipped to handle the intricacies of ERP installation, configuration, customization, and ongoing maintenance. Patches, upgrades, security updates, and troubleshooting became responsibilities that often fell on already stretched staff, detracting from their core duties. The time and resources consumed by these tasks were disproportionate to the size and financial capacity of the business, leading to delayed implementations, budget overruns, and a general reluctance to adopt such systems. Consequently, many small manufacturers continued to rely on a patchwork of disconnected spreadsheets, manual processes, and disparate software solutions, leading to inefficiencies that stifled their potential for substantial growth and competitiveness.

The Economic Edge: Cost-Effectiveness of Cloud ERP for Manufacturers

One of the most compelling arguments for ERP in the Cloud as a game changer for small manufacturing growth is its profound impact on financial viability. The shift from a capital expenditure (CapEx) model to an operational expenditure (OpEx) model is revolutionary for businesses with limited financial bandwidth. This fundamental change transforms an overwhelming upfront cost into predictable, manageable monthly subscriptions, making advanced enterprise software genuinely accessible.

With cloud ERP, small manufacturers no longer need to invest heavily in purchasing and maintaining expensive server hardware, complex networking equipment, or perpetual software licenses. All these infrastructure components are managed by the cloud provider. This eliminates the need for large initial capital outlays, freeing up valuable funds that can be reinvested into core manufacturing activities, such as purchasing new production machinery, expanding product lines, or investing in marketing and sales initiatives. The subscription-based pricing model also allows for greater financial predictability, making budgeting much simpler and reducing the risk of unexpected IT costs. This financial flexibility is critical for small businesses that need to carefully manage their cash flow.

Furthermore, the total cost of ownership (TCO) for cloud ERP is significantly lower over the long term. Beyond the initial hardware and software costs, traditional ERP systems incur substantial ongoing expenses related to maintenance, power consumption for servers, cooling systems, and the salaries of specialized IT personnel required to manage the infrastructure. Cloud ERP providers handle all these aspects, including system updates, security patches, and backups, as part of the subscription fee. This drastically reduces the need for an in-house IT team dedicated solely to ERP management, allowing existing staff to focus on more strategic initiatives. For a small manufacturer, this means a leaner operational structure and a more efficient allocation of human resources, directly contributing to their ability to achieve sustainable growth and scale without the prohibitive overheads associated with legacy systems.

Unleashing Agility: Scalability and Flexibility with Cloud ERP

In the dynamic world of manufacturing, especially for small businesses aspiring to grow, agility and the ability to scale operations quickly are paramount. ERP in the Cloud is a true game changer in this regard, offering unparalleled scalability and flexibility that simply isn’t feasible with traditional on-premise systems. As a small manufacturer expands, its IT needs grow; cloud ERP is designed to accommodate this expansion seamlessly and cost-effectively.

Imagine a scenario where your manufacturing business secures a major new contract, doubling your production output and requiring more users to access the system, additional modules for new functionalities, or increased storage capacity for new data. With on-premise ERP, such expansion would necessitate purchasing and installing new servers, upgrading software licenses, and often enduring significant downtime and complex migrations. This process can be slow, expensive, and disruptive, potentially hindering your ability to capitalize on growth opportunities. Cloud ERP, however, offers “elasticity.” You can easily add or remove users, activate new modules, or increase storage and processing power with just a few clicks, often without any disruption to ongoing operations. This “pay-as-you-grow” model ensures that you only pay for the resources you actually need, allowing you to scale up during peak seasons or periods of rapid expansion, and even scale down during slower periods, optimizing your operational costs.

This inherent flexibility extends beyond just user count and capacity. Cloud ERP solutions are often designed with modularity in mind, allowing small manufacturers to start with core functionalities like production and inventory management, and then add advanced features such as customer relationship management (CRM), supply chain planning, or quality management as their business needs evolve. This phased approach to implementation reduces initial complexity and allows businesses to adapt the system precisely to their evolving requirements without a complete overhaul. For a small manufacturing business, this means having an ERP system that truly grows with them, adapting to market changes and business expansion without becoming a bottleneck, thereby acting as a critical enabler for sustained development and market responsiveness.

Anytime, Anywhere: The Power of Remote Accessibility for Modern Manufacturing

In an increasingly globalized and remote-friendly world, the ability to access critical business information and manage operations from anywhere, at any time, is no longer a luxury but a necessity. For small manufacturing businesses, particularly those with distributed teams, multiple production sites, or owners who travel frequently, the remote accessibility offered by ERP in the Cloud is a profound game changer, enhancing efficiency and responsiveness.

Unlike traditional on-premise systems that typically require direct access to internal networks or complex VPN setups, cloud ERP solutions are accessed simply via a web browser or a dedicated mobile application, provided there’s an internet connection. This means that a production manager can check inventory levels from a trade show, a sales representative can confirm order status with a client while on the road, or a finance director can approve invoices from their home office. This level of immediate access eliminates geographical barriers and time constraints, fostering a more agile and responsive operation. It ensures that decision-makers always have the most current information at their fingertips, leading to faster problem-solving and more informed strategic choices, which are crucial for maintaining a competitive edge and driving growth in the fast-paced manufacturing sector.

Furthermore, remote accessibility significantly enhances collaboration across different departments and even with external stakeholders like suppliers and customers. Teams can work concurrently on projects, view real-time production schedules, and update order statuses without being physically in the same building. This is particularly beneficial for small manufacturers who might be exploring new business models, such as drop-shipping components or managing outsourced production, as it allows for seamless communication and data exchange across the entire supply chain. The ability to empower employees to work effectively regardless of their physical location not only improves productivity and employee satisfaction but also builds resilience, ensuring business continuity even in unforeseen circumstances, thereby safeguarding the growth trajectory of the small manufacturing enterprise.

Fortifying Your Data: Cloud ERP Security Measures and Compliance

A common initial concern for businesses contemplating the move to the cloud, especially for small manufacturers dealing with sensitive proprietary data, is security. However, for ERP in the Cloud, leading providers offer robust security measures that often surpass what a small manufacturing business could realistically achieve on its own with an on-premise setup. This aspect of heightened security makes cloud ERP a significant game changer, allowing smaller firms to operate with greater peace of mind regarding their invaluable business data.

Cloud ERP vendors specialize in data security, investing heavily in advanced technologies, dedicated security teams, and compliance certifications that are typically out of reach for individual small businesses. They employ multi-layered security protocols, including sophisticated encryption for data in transit and at rest, stringent access controls, regular security audits, intrusion detection systems, and disaster recovery plans. These measures protect your manufacturing data from cyber threats, unauthorized access, and data loss. Furthermore, reputable cloud providers adhere to international and industry-specific compliance standards (such as ISO 27001, SOC 1/2, GDPR, HIPAA, etc.), ensuring that your data management practices meet rigorous regulatory requirements, which is increasingly important for supply chain transparency and customer trust.

Entrusting your data to a cloud ERP provider effectively means leveraging their expertise and substantial resources for your data protection. While an on-premise system requires your small manufacturing business to be solely responsible for firewalls, patching servers, managing backups, and responding to security incidents—tasks that can quickly overwhelm a limited IT staff—cloud ERP offloads this critical burden. This allows your team to focus on core manufacturing processes and innovation, rather than constantly worrying about data breaches or system failures. The superior security posture offered by cloud ERP providers significantly mitigates risks, ensuring the integrity and availability of your operational data, which is paramount for maintaining business continuity and sustaining the momentum of small manufacturing growth.

Staying Current: Automatic Updates and Reduced IT Burden

One of the often-underestimated benefits of ERP in the Cloud that acts as a significant game changer for small manufacturing businesses is the automatic updates and the resulting reduction in IT burden. Traditional on-premise ERP systems famously demand significant time, effort, and resources for routine maintenance, software patches, and major version upgrades. These tasks can be disruptive, resource-intensive, and often require specialized IT skills that small manufacturers might not possess in-house.

With a cloud ERP solution, the vendor is responsible for all software updates, patches, and version upgrades. These are typically rolled out seamlessly in the background, often during off-peak hours, ensuring that your manufacturing operations are always running on the latest version of the software with the newest features, security enhancements, and bug fixes. This eliminates the need for your staff to manually download, test, and install updates, which can be a complex and time-consuming process fraught with potential compatibility issues. This continuous improvement model ensures that your system remains agile and cutting-edge without you having to lift a finger, freeing up valuable internal resources that would otherwise be tied up in IT maintenance tasks.

For a small manufacturing business, this translates into substantial operational efficiency and cost savings. You no longer need to allocate budget for expensive upgrade projects or hire dedicated IT personnel solely for ERP maintenance. Your existing team, often comprising a few multi-skilled individuals, can focus on strategic initiatives that directly contribute to production efficiency, product innovation, and customer satisfaction, rather than routine system upkeep. This significant reduction in IT overhead, combined with constant access to the most advanced features and robust security, allows small manufacturers to leverage enterprise-grade technology without the typical associated headaches, truly empowering them to concentrate on growth and competitive advantage.

Breaking Down Silos: Enhanced Collaboration and Data Flow

Effective collaboration and seamless data flow are critical arteries of any successful manufacturing operation, and the lack thereof is a significant impediment for many small businesses. Disconnected departmental systems, manual data entry, and fragmented communication channels often lead to errors, delays, and a lack of holistic visibility. This is precisely where ERP in the Cloud truly shines as a game changer, fostering a highly collaborative environment and ensuring accurate, real-time data flow across the entire organization.

By centralizing all business data into a single, integrated platform, cloud ERP eliminates data silos. Information entered by the sales team, for instance, immediately becomes accessible to production planning, inventory management, and finance. When an order is placed, the system can automatically check raw material availability, schedule production, update delivery timelines, and generate invoices, all without manual intervention or data re-entry. This integration prevents discrepancies that arise from duplicate data entry or outdated information in different departmental spreadsheets. It ensures that everyone in the organization, from the shop floor to the executive suite, is working from the same, accurate, and most current set of data, fostering consistency and reducing operational friction.

This unified data environment significantly enhances collaboration. For example, if a customer calls about an order, the sales representative can instantly access production status, shipping details, and billing information from a single screen, providing immediate and accurate answers. Production managers can collaborate seamlessly with procurement teams by viewing real-time inventory levels and predicted demand, optimizing purchasing decisions. Engineers can access historical production data to inform new product designs, and finance can track costs and revenues directly tied to specific production runs. This interconnectedness streamlines processes, improves communication, reduces miscommunications, and accelerates decision-making across the entire small manufacturing enterprise. The resulting synergy leads to greater operational efficiency, improved customer satisfaction, and ultimately, accelerated growth fueled by truly cohesive teamwork and data-driven insights.

Smarter Decisions: Real-Time Insights for Sustainable Growth

In the fast-paced world of manufacturing, timely and accurate decision-making can be the difference between stagnation and significant growth. Many small manufacturing businesses struggle with making informed strategic decisions due to fragmented data, outdated reports, and a reliance on gut feelings. This is where ERP in the Cloud acts as a genuine game changer, providing unprecedented access to real-time insights and robust reporting capabilities that empower businesses to make smarter, data-driven decisions that directly contribute to their sustained success.

Because cloud ERP integrates all core business functions – from sales and production to inventory and finance – it collects a vast amount of operational data in one centralized repository. This real-time data, unlike historical reports generated from disconnected systems, provides an up-to-the-minute snapshot of your manufacturing operations. You can instantly view current inventory levels, work-in-progress status, production bottlenecks, sales order backlogs, and financial performance. This immediate visibility allows management to identify trends, spot anomalies, and react quickly to changing market conditions or internal challenges. For example, if raw material prices suddenly spike, an integrated ERP can immediately show the impact on current production costs and future profitability, enabling management to adjust pricing, explore alternative suppliers, or optimize production schedules proactively.

Beyond simple reporting, many cloud ERP solutions offer advanced analytics and business intelligence (BI) dashboards. These tools transform raw data into actionable insights, presenting complex information in easy-to-understand visual formats. Small manufacturers can track key performance indicators (KPIs) like production efficiency, order fulfillment rates, customer acquisition costs, and profit margins in real-time. This deep analytical capability allows for predictive modeling, identifying potential issues before they escalate, and pinpointing areas for process improvement. By moving from reactive problem-solving to proactive strategic planning based on accurate, real-time data, small manufacturing businesses can optimize their resources, identify new opportunities, mitigate risks, and confidently chart a course for sustainable growth and enhanced profitability in a competitive landscape.

Optimizing the Core: Production and Inventory Management Excellence

For any manufacturing business, the twin pillars of production and inventory management are absolutely critical for efficiency, cost control, and customer satisfaction. In small manufacturing operations, these processes are often managed manually or through basic spreadsheets, leading to inefficiencies, stockouts, overstocking, and production delays. ERP in the Cloud emerges as a profound game changer by bringing sophisticated, integrated control to these core functions, unlocking significant operational excellence.

Cloud ERP systems provide comprehensive modules specifically designed for production planning and control. They enable detailed bill of materials (BOM) management, allowing for accurate tracking of components and sub-assemblies. Production scheduling can be optimized based on available resources, machine capacity, and order priorities, ensuring smooth workflows and minimizing bottlenecks on the shop floor. Real-time data collection from production lines can feed directly into the ERP, providing immediate updates on work-in-progress (WIP), completed units, and identifying any deviations from planned schedules. This granular visibility allows small manufacturers to pinpoint inefficiencies, adjust production runs on the fly, and ensure that products are manufactured on time and within budget, directly impacting delivery reliability and customer trust.

Simultaneously, the inventory management capabilities of cloud ERP are transformative. The system provides a real-time, accurate view of all inventory across multiple locations, including raw materials, WIP, and finished goods. Automated tracking of incoming and outgoing inventory, optimized reorder points, and demand forecasting based on sales data help prevent costly stockouts that halt production, as well as wasteful overstocking that ties up capital and incurs storage costs. Integration with purchasing means purchase orders can be automatically generated when stock levels hit predefined thresholds, streamlining procurement. By optimizing inventory turns and reducing carrying costs, small manufacturers can significantly improve their cash flow and profitability. This level of integrated control over production and inventory is a fundamental shift for many small businesses, making ERP in the Cloud an indispensable tool for achieving operational excellence and supporting their ambitious growth objectives.

Financial Foresight: Integrating Money Matters for Greater Control

While often perceived as an operational tool, the impact of ERP in the Cloud on a small manufacturing business’s financial health and control is nothing short of revolutionary. For many smaller firms, financial management often involves disconnected accounting software, manual invoice processing, and retroactive reporting, making it difficult to gain real-time insights into cash flow, profitability, and cost centers. Cloud ERP serves as a crucial game changer by seamlessly integrating all financial processes, providing unparalleled visibility and control over money matters.

The financial modules within a cloud ERP system centralize all accounting functions, including general ledger, accounts payable, accounts receivable, budgeting, and financial reporting. Because the system is integrated with other modules like sales, purchasing, and production, every transaction automatically flows through to the financial records. When a sales order is placed, an invoice is generated; when raw materials are purchased, the cost is immediately recorded; when production consumes materials, their value is updated in inventory and cost of goods sold. This real-time synchronization eliminates manual data entry, reduces errors, and ensures that financial statements are always up-to-date and accurate, providing a true and current picture of the company’s financial standing.

This holistic financial integration empowers small manufacturers with powerful analytical capabilities. You can generate detailed financial reports – profit and loss statements, balance sheets, cash flow statements – at any time, not just at month-end. Furthermore, you can track costs down to individual production runs, specific products, or even customer segments, allowing for precise cost analysis and informed pricing strategies. Better budgeting tools and forecasting capabilities, leveraging historical data from across the enterprise, enable more accurate financial planning. For a small manufacturing business, this improved financial foresight leads to better cash flow management, enhanced profitability analysis, and the ability to make proactive financial decisions that directly support strategic growth initiatives, effectively transforming raw financial data into actionable intelligence.

Beyond the Factory Floor: CRM and SCM Synergies with Cloud ERP

The impact of ERP in the Cloud for small manufacturing growth extends far beyond the confines of the factory floor, deeply influencing critical external-facing functions like customer relationship management (CRM) and supply chain management (SCM). While often managed by separate systems or ad-hoc processes in smaller businesses, the integration of these functions within a cloud ERP framework creates powerful synergies that are truly a game changer for overall business performance and competitive advantage.

Integrating CRM capabilities directly into the ERP allows for a 360-degree view of the customer. Sales teams can access real-time inventory levels, production schedules, and delivery timelines directly from their customer interaction platform. This means quicker, more accurate responses to customer inquiries, reliable order fulfillment promises, and proactive communication regarding potential delays. Post-sales, the system tracks service history, warranty claims, and customer feedback, feeding valuable insights back to product development and quality control. This seamless flow of customer data ensures a consistent and superior customer experience, fostering loyalty and repeat business, which are vital for sustainable growth in small manufacturing. When every department has access to a unified customer record, the entire organization works in concert to serve the customer better.

Similarly, robust SCM integration within a cloud ERP solution transforms how small manufacturers manage their network of suppliers and distributors. The system can automate procurement processes, from generating purchase orders based on real-time inventory and production needs to tracking supplier performance and managing contracts. It provides visibility into the entire supply chain, from raw material sourcing to final product delivery, helping to identify potential bottlenecks or risks. By optimizing supplier relationships, negotiating better terms, and ensuring a steady flow of materials, manufacturers can reduce costs, improve lead times, and enhance their ability to respond to market demands. This comprehensive integration of CRM and SCM with core ERP functions positions the small manufacturer to not only streamline internal operations but also to forge stronger external relationships, resulting in a more resilient, responsive, and growth-oriented business model.

Navigating the Transition: Implementation and Adoption of Cloud ERP

While ERP in the Cloud offers undeniable advantages, the successful transition from legacy systems or manual processes to a new enterprise-wide platform requires careful planning and execution. For small manufacturing businesses, the thought of implementing such a comprehensive system can seem daunting, but approaching it strategically can make the process smooth and effective, ultimately serving as a game changer for long-term operational efficiency.

The implementation process for cloud ERP is generally faster and less complex than for on-premise solutions due to the lack of hardware setup and reduced customization requirements. However, it still involves several critical steps. Firstly, a thorough assessment of your current business processes and pain points is essential. Defining your specific needs and objectives for the ERP system will guide the selection of the right solution and modules. Secondly, data migration is a crucial phase, involving cleaning and transferring existing data from disparate sources into the new system. This step requires meticulous attention to detail to ensure data accuracy and integrity, as clean data is the foundation of effective ERP utilization. It’s also important to configure the system to match your specific workflows, which might involve some level of customization or integration with other existing specialized software.

Perhaps the most critical aspect of successful adoption for a small manufacturing business is user training and change management. Even the most advanced cloud ERP system will fail if employees don’t understand how to use it or resist the new processes. Comprehensive training programs, tailored to different user roles (e.g., production staff, sales, finance), are vital to ensure that everyone feels comfortable and proficient with the new system. Communicating the benefits of the ERP system clearly, addressing concerns proactively, and involving key users in the planning and testing phases can foster enthusiasm and smooth the transition. By investing in proper training and change management, small manufacturers can ensure that their employees embrace the new system, unlock its full potential, and truly leverage ERP in the Cloud as a catalyst for sustainable growth and operational transformation.

Overcoming Hurdles: Addressing Common Concerns of Cloud ERP Adoption

Despite the overwhelming advantages, small manufacturing businesses often harbor legitimate concerns when considering the adoption of ERP in the Cloud. Addressing these potential hurdles proactively is key to a successful implementation and realizing the full game-changing potential of the technology. Common worries typically revolve around data control, vendor reliance, customization limitations, and the perceived complexity of the transition.

One of the primary concerns is data ownership and security, as the data is no longer housed on premise. While we’ve discussed the enhanced security measures by reputable cloud providers, it’s crucial for small manufacturers to thoroughly vet potential vendors, understand their data privacy policies, data recovery protocols, and ensure compliance with relevant industry regulations. Strong service level agreements (SLAs) regarding uptime and data access are also essential. Another concern often cited is vendor lock-in, where businesses fear becoming overly dependent on a single provider. Mitigating this involves choosing vendors with a strong reputation for open APIs and easy data export capabilities, ensuring flexibility should future needs dictate a change. It’s important to select a solution that offers sufficient flexibility to integrate with other essential tools you might already use, or plan to use, as your manufacturing business grows.

Furthermore, while cloud ERP typically offers extensive configuration options, some small manufacturers worry about limitations on deep customization that might be available with on-premise systems. It’s true that extreme custom coding is less common in the SaaS model, but modern cloud ERPs are designed with flexibility in mind, offering low-code/no-code options for process automation, robust integration capabilities with other applications, and industry-specific modules that cater to unique manufacturing needs. The benefit here is that upgrades are simpler and less costly without highly customized code. Finally, the perceived complexity of implementation and training, despite generally being easier than on-premise systems, remains a mental barrier. Partnering with experienced implementation consultants and dedicating internal resources for the project, coupled with a phased approach to rollout, can significantly ease this transition. By addressing these concerns head-on, small manufacturing businesses can confidently move forward, recognizing that the long-term benefits of ERP in the Cloud far outweigh these initial reservations, paving the way for truly transformative growth.

Choosing Wisely: Key Considerations for Your Manufacturing Business

The decision to adopt ERP in the Cloud is a strategic one, and for small manufacturing businesses, choosing the right solution is paramount to leveraging its full potential as a game changer. The market offers a diverse range of cloud ERP providers, each with different strengths, features, and pricing models. A thorough evaluation process, tailored to your specific business needs and future growth aspirations, is critical for making an informed choice that will genuinely drive your operational efficiency and overall success.

Firstly, consider your industry-specific needs. Manufacturing is a broad sector, and your specific niche (e.g., discrete manufacturing, process manufacturing, make-to-order, engineer-to-order) will dictate certain functionalities. Look for cloud ERP solutions that have strong modules for bill of materials, production scheduling, quality control, lot tracking, and perhaps even advanced planning and scheduling (APS) if your operations are complex. A general business ERP might not have the depth of manufacturing-specific features your small business requires. Secondly, evaluate scalability and flexibility. As discussed, your chosen system must be able to grow with your business, easily accommodating more users, new locations, and additional modules without requiring a complete system overhaul. Assess how easily new functionalities can be added and how well the system integrates with other specialized software you might use, such as CAD software or shop floor control systems.

Finally, equally important are the vendor’s reputation, support, and pricing structure. Research client testimonials, case studies, and industry reviews to gauge the vendor’s reliability and customer satisfaction. A robust customer support system, including technical assistance, training resources, and community forums, is crucial, especially for small businesses without extensive in-house IT support. Understand the pricing model thoroughly, including subscription fees, implementation costs, potential add-on module charges, and any hidden fees. Compare total cost of ownership over several years. By carefully weighing these factors, a small manufacturing business can select a cloud ERP system that not only meets current demands but also serves as a strategic partner, effectively becoming the technology backbone for sustained growth and continuous improvement in a competitive market.

The Future is Now: Emerging Technologies and Cloud ERP Integration

The transformative power of ERP in the Cloud for small manufacturing growth is not a static phenomenon; it’s continuously evolving, integrating with cutting-edge technologies that promise even greater efficiencies and opportunities. As manufacturing enters a new era of Industry 4.0, the synergy between cloud ERP and emerging technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) is truly a game changer, allowing even small players to compete at an advanced level.

IoT integration allows manufacturing equipment and sensors on the shop floor to feed real-time data directly into the cloud ERP system. This data can include machine uptime, performance metrics, energy consumption, and product quality parameters. By analyzing this continuous stream of information, the ERP can provide instant insights into production bottlenecks, predict equipment failures before they occur (predictive maintenance), and optimize resource utilization. Imagine a scenario where a machine reports an impending issue, and the ERP automatically triggers a maintenance request, orders necessary parts, and adjusts the production schedule to minimize disruption. This level of proactive management significantly reduces downtime, enhances productivity, and lowers operational costs for small manufacturers.

Furthermore, AI and ML capabilities embedded within or integrated with cloud ERP systems are revolutionizing forecasting, quality control, and process optimization. AI algorithms can analyze vast datasets from sales history, market trends, and supply chain dynamics to provide highly accurate demand forecasts, optimizing inventory levels and production planning far beyond traditional methods. ML can be used to identify patterns in production data, improving quality control by predicting defects or optimizing machine settings for better output. For a small manufacturer, leveraging these advanced technologies through their cloud ERP means moving from reactive decision-making to predictive intelligence, gaining a profound competitive edge in terms of efficiency, product quality, and market responsiveness. This forward-looking integration ensures that ERP in the Cloud remains not just a current game changer but a foundational platform for future innovation and sustained growth in the evolving manufacturing landscape.

Conclusion: Seizing the Growth Opportunity with Cloud ERP

The journey of a small manufacturing business in today’s intricate economic climate is fraught with challenges, yet ripe with unparalleled opportunities for those willing to embrace digital transformation. For too long, sophisticated enterprise resource planning systems were exclusive domains of large corporations, largely inaccessible due to their prohibitive costs and complex infrastructure requirements. However, the advent and maturity of ERP in the Cloud have fundamentally democratized access to this powerful technology, truly making it a game changer for small manufacturing growth.

As we’ve explored, moving your ERP to the cloud offers a multifaceted array of benefits: from the compelling cost-effectiveness of an OpEx model and the unparalleled scalability that grows with your business, to the security and accessibility that empower your team regardless of location. It breaks down data silos, fosters collaboration, and provides real-time, actionable insights that drive smarter decision-making. Beyond core operations, it profoundly impacts production and inventory management, strengthens financial control, and creates powerful synergies with customer relationship management and supply chain operations. These integrated capabilities not only streamline current processes but also lay a robust foundation for future innovation, particularly as new technologies like AI and IoT become increasingly intertwined with cloud platforms.

For a small manufacturer looking to not just survive but thrive, compete effectively, and achieve substantial growth in the modern era, embracing ERP in the Cloud is no longer just an option—it’s a strategic imperative. It’s about shedding the inefficiencies of fragmented systems and manual processes, embracing agility, and empowering your business with the same level of operational intelligence and control that larger competitors possess, but with a much lower barrier to entry. The future of manufacturing is digital, integrated, and cloud-powered. By seizing this opportunity, your small manufacturing business can unlock its full potential, achieve operational excellence, and confidently chart a course for sustained success in the decades to come. Don’t let your competition leave you behind; explore how ERP in the Cloud: A Game Changer for Small Manufacturing Growth can transform your enterprise today.