Retail, at its heart, is a delicate dance between bringing products to market and ensuring they reach customers efficiently and profitably. However, an invisible foe often lurks in the shadows of every retail operation: shrinkage. This seemingly benign term encompasses a multitude of losses that can silently erode profits, ranging from theft to administrative errors. Tackling shrinkage isn’t just about catching culprits; it’s about building a robust system that inherently prevents these losses. This is where an Enterprise Resource Planning (ERP) system steps onto the stage, not merely as a software solution, but as a formidable ally in safeguarding retail inventory. Understanding ERP’s role in preventing shrinkage in retail inventory is paramount for any business aiming for sustainable growth and operational excellence.

For too long, retailers have grappled with fragmented systems, manual processes, and a general lack of real-time visibility into their stock. These inefficiencies create fertile ground for shrinkage to flourish, making it incredibly challenging to pinpoint exactly where losses are occurring and, more importantly, how to stop them. An ERP system acts as the central nervous system of a retail business, integrating various functions from sales and marketing to supply chain and finance. By providing a unified, holistic view of operations, ERP systems empower retailers with the data and control necessary to significantly mitigate, if not entirely eliminate, the myriad causes of inventory shrinkage. This deep dive will explore the multifaceted ways in which a well-implemented ERP solution can transform your retail business’s approach to loss prevention, turning potential liabilities into opportunities for greater efficiency and profitability.

Unpacking Retail Shrinkage: Beyond Simple Theft

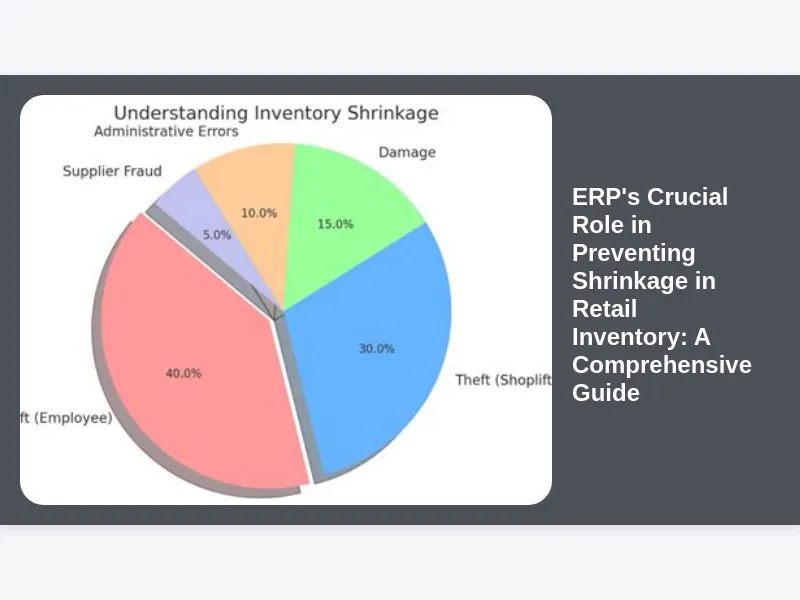

Before we delve into ERP’s role in preventing shrinkage in retail inventory, it’s essential to truly grasp the scope and complexity of what “shrinkage” actually entails. Many immediately think of shoplifting when the term shrinkage is mentioned, but this is merely one facet of a much larger, more insidious problem. Shrinkage refers to the difference between the inventory recorded in a company’s books and the actual physical inventory available. This discrepancy can arise from a multitude of sources, each chipping away at a retailer’s bottom line in subtle yet significant ways. It’s a pervasive issue that impacts retailers of all sizes, across all sectors, and understanding its various origins is the first step toward effective mitigation.

The causes of retail shrinkage are broadly categorized into four main areas: external theft, internal theft, administrative errors, and vendor fraud. External theft, primarily shoplifting, remains a significant concern, with organized retail crime networks contributing to substantial losses. Internal theft, often more damaging due to its hidden nature, includes employee theft of cash or merchandise, sweethearting (giving unauthorized discounts to friends/family), or even more elaborate embezzlement schemes. Administrative errors, though seemingly benign, can account for a considerable portion of shrinkage; these include mistakes in receiving, shipping, pricing, data entry, or inventory counting. Finally, vendor fraud encompasses issues like short-shipping products, invoicing for goods not delivered, or delivering damaged items that are not properly accounted for. Each of these categories presents unique challenges that demand a sophisticated, integrated solution, which is precisely where an advanced ERP system proves invaluable.

The Traditional Inventory Challenges Facing Retailers

Historically, managing retail inventory has been a Herculean task, fraught with challenges that directly contribute to shrinkage. Many retailers, especially smaller ones or those operating with legacy systems, still rely on manual processes, disparate spreadsheets, and fragmented departmental operations. This approach creates an environment ripe for inaccuracies and vulnerabilities, making effective retail inventory management an elusive goal. Without a unified system, information about stock levels, sales, returns, and orders resides in silos, making it nearly impossible to get a real-time, accurate picture of what’s truly available versus what’s recorded. This lack of transparency is a primary enabler of shrinkage.

Consider the journey of a product from supplier to customer: it’s ordered, received, stored, moved within the warehouse or store, sold, and sometimes even returned. At each of these touchpoints, there’s a potential for error or malfeasance. Manual receiving processes can lead to miscounts, incorrect item identifications, or failure to properly record damaged goods. Relying on periodic physical counts means that any discrepancies are only discovered much later, long after the opportunity to investigate and rectify the issue has passed. Furthermore, disjointed systems mean that a sale recorded at the Point of Sale (POS) might not immediately update the inventory system, leading to phantom stock or overselling. These traditional challenges underscore the urgent need for a more integrated, automated, and intelligent approach to inventory control, an approach perfectly embodied by a modern ERP system.

ERP as the Central Nervous System for Retail Operations

Imagine a retail business as a complex organism, with various departments and functions acting as its organs. Without a brain and a nervous system to coordinate everything, these organs would operate in isolation, leading to chaos and inefficiency. This is precisely the role an ERP system plays in a retail environment: it acts as the central nervous system, integrating all core business processes into a single, unified database and application suite. From procurement and inventory management to sales, customer service, and financial reporting, ERP brings everything under one digital roof. This integration is not just about convenience; it’s about creating a single source of truth for all business data, which is foundational to combating shrinkage.

The power of an ERP lies in its ability to break down departmental silos and provide supply chain visibility across the entire operation. When a product is ordered, its status is immediately visible to procurement, warehouse, and sales teams. When it’s received, inventory levels are updated in real-time. When it’s sold, stock counts adjust instantly. This seamless flow of information ensures that everyone is working from the same accurate data, dramatically reducing the chances of errors that lead to shrinkage. Moreover, this integrated approach fosters a culture of accountability and transparency, as every transaction, every movement of goods, and every financial entry is meticulously recorded and traceable. It’s this holistic integration that makes ERP an indispensable tool in any comprehensive loss prevention strategy.

Enhanced Inventory Accuracy: A Cornerstone of Shrinkage Prevention

One of the most profound ways an ERP system contributes to ERP’s role in preventing shrinkage in retail inventory is by dramatically enhancing inventory accuracy. Inaccurate inventory counts are a leading cause of administrative shrinkage, leading to phantom stock, overselling, or holding dead stock. Traditional methods often rely on manual data entry, which is inherently prone to human error, or periodic physical counts, which are disruptive, labor-intensive, and provide only a snapshot in time. An ERP system, particularly one integrated with barcode scanning, RFID technology, or other automated data capture methods, transforms this landscape entirely.

With an ERP, every inventory movement, from the moment goods arrive at the loading dock to when they are sold and leave the store, is meticulously recorded and updated in real-time. When a shipment is received, items are scanned into the system, automatically updating stock levels. As items are picked for orders, transferred between locations, or sold at the POS, the ERP system adjusts inventory counts instantly. This real-time tracking provides an unprecedented level of precision, ensuring that the inventory records accurately reflect the physical reality. By minimizing discrepancies between theoretical and actual stock, ERP systems significantly reduce the opportunities for administrative errors to contribute to shrinkage. This precision allows retailers to trust their data, making better decisions about purchasing, stocking, and sales strategies, ultimately safeguarding profits.

Optimizing Procurement and Receiving to Minimize Early Losses

Shrinkage can begin even before products hit the sales floor, specifically during the procurement and receiving stages. Discrepancies between what was ordered and what was received, or unrecorded damage during transit, are common sources of loss. This is another area where ERP’s role in preventing shrinkage in retail inventory shines through. A robust ERP system streamlines the entire purchasing and receiving process, establishing critical checks and balances that minimize errors and detect potential vendor fraud.

When an order is placed through an ERP’s procurement module, it generates a clear, traceable record. Upon arrival of goods, the receiving team uses the ERP system to cross-reference the incoming shipment against the original purchase order. This comparison instantly flags any discrepancies, such as short shipments, over-shipments, or items that weren’t ordered. Integrated quality control features allow for immediate recording of damaged goods, ensuring they are either returned to the vendor or properly written off, rather than disappearing into an unaccounted “black hole.” By automating this reconciliation process and providing immediate alerts for mismatches, ERP systems prevent losses that would otherwise go unnoticed, effectively closing loopholes that opportunistic vendors or internal actors might exploit. This rigorous control at the point of entry sets a strong foundation for overall operational efficiency and shrinkage reduction.

Streamlined Warehouse Management and Stock Movement

Beyond the initial receiving, the journey of inventory within a warehouse or store can also be a significant source of shrinkage due to misplacement, damage, or unauthorized removal. This is where an ERP system, often integrated with or encompassing a Warehouse Management System (WMS) module, becomes invaluable for real-time inventory tracking. By dictating precise put-away locations, optimizing picking routes, and recording every internal transfer, an ERP system ensures that items are always where they are supposed to be. This level of granular control greatly reduces the likelihood of goods being lost or misplaced within the facility.

Every movement of an item, whether from receiving to storage, between different storage zones, or from the backroom to the sales floor, is digitally logged within the ERP. Using mobile scanners and tablets integrated with the ERP, warehouse staff can confirm locations and quantities, instantly updating the system. This not only enhances efficiency but also creates a comprehensive audit trail for every piece of inventory. If an item goes missing, the ERP can provide a detailed history of its last known location and who handled it, facilitating investigations and deterring internal theft. Furthermore, features like FIFO (First-In, First-Out) stock rotation, guided by the ERP, help manage expiry dates and prevent obsolescence or damage, reducing another common form of shrinkage.

The Power of Point-of-Sale (POS) Integration

The point of sale is a critical juncture where inventory leaves the retail environment, and it’s also a common area for both external and internal theft. Without proper integration, POS systems can operate in isolation from inventory records, creating vulnerabilities. ERP’s role in preventing shrinkage in retail inventory is significantly amplified through seamless POS integration, ensuring that every sale instantly and accurately reflects in the central inventory database. This immediate update is crucial for maintaining precise stock accuracy.

When a product is scanned at the POS, the ERP’s inventory module is updated in real-time, decrementing the stock count. This prevents issues like “phantom stock” (where an item shows as available in the system but is actually sold out) and ensures that actual sales figures align perfectly with inventory movements. Beyond simple stock updates, advanced POS-ERP integration can also track returns, exchanges, and voids with detailed audit trails, making it harder for employees to commit return fraud or “no-sale” theft. By linking sales data directly to inventory, the ERP system provides a holistic view of product flow, enabling retailers to identify patterns of suspicious activity, whether it’s excessive voids at a particular register or unusual return rates for specific items. This level of transparency and control at the point of transaction is a powerful deterrent against various forms of shrinkage.

Deterring Internal Theft Through Robust Audit Trails and Access Controls

Employee theft is often cited as a major contributor to retail shrinkage, sometimes even surpassing external theft in terms of financial impact. Its insidious nature makes it difficult to detect, as it often involves trusted individuals. This is where ERP’s role in preventing shrinkage in retail inventory becomes particularly vital through its capabilities for creating robust audit trails and implementing stringent access controls. A well-configured ERP system can dramatically reduce opportunities for internal theft by increasing accountability and transparency across all operations.

Every action taken within the ERP system, from receiving new stock to adjusting inventory levels, processing sales, or issuing refunds, is logged with a timestamp and the user’s identity. This comprehensive audit trail means that any discrepancy can be traced back to the specific transaction and the individual responsible. If an inventory adjustment is made, the system records who made it, when, and why. This level of traceability acts as a powerful deterrent, as employees know their actions are being monitored and recorded. Furthermore, ERP systems allow for granular access controls, ensuring that employees only have access to the functions and data necessary for their roles. For instance, a cashier won’t have the permissions to make inventory adjustments, and a warehouse employee won’t be able to process refunds. By limiting access and creating transparent records, ERP systems significantly reduce the avenues for internal theft and fraud, making it an indispensable component of any retail security solution.

Minimizing Administrative Errors and Data Entry Mistakes

While external and internal theft often grab headlines, administrative errors are silent, persistent contributors to retail shrinkage, sometimes accounting for a significant portion of losses. These errors can occur at any stage: miscounting items during receiving, incorrect data entry for product details, inaccurate price changes, or misplacing items during inventory transfers. Individually, these mistakes might seem minor, but cumulatively, they can lead to substantial discrepancies between recorded and actual inventory. ERP’s role in preventing shrinkage in retail inventory is exceptionally strong in this area through automation and standardization.

An ERP system drastically reduces the reliance on manual data entry by automating many processes. For example, instead of manually typing in product details or quantities, items can be scanned, automatically pulling information from the product master data. When prices change, these updates can be centrally managed within the ERP and automatically pushed to all relevant systems, including POS terminals and e-commerce platforms, eliminating pricing errors. The system can also enforce standard operating procedures, guiding users through processes to minimize mistakes. By centralizing data and automating routine tasks, an ERP system significantly reduces the opportunities for human error, ensuring that inventory records are accurate and consistent. This not only directly mitigates administrative shrinkage but also frees up staff to focus on more value-added activities, contributing to overall operational efficiency.

Smarter Demand Forecasting and Obsolescence Management

Shrinkage isn’t just about items disappearing; it also includes losses from products that become unsellable due to damage, expiry, or obsolescence. Holding excess inventory ties up capital and increases the risk of these losses. This is where ERP’s role in preventing shrinkage in retail inventory extends beyond direct security measures to more strategic inventory planning. By integrating historical sales data, seasonal trends, promotional impacts, and even external factors like economic forecasts, an ERP’s advanced analytics capabilities can significantly improve demand forecasting.

Accurate demand forecasting allows retailers to optimize their purchasing decisions, ensuring they order just enough stock to meet anticipated customer needs without over-ordering. This reduces the risk of holding excessive inventory that might expire (e.g., food, cosmetics), go out of fashion (e.g., apparel), or become obsolete (e.g., electronics). The ERP system can track product shelf life, alerting managers to items nearing their expiry date so they can be discounted, moved, or donated before becoming a total loss. Furthermore, by identifying slow-moving or stagnant inventory, retailers can take proactive steps to liquidate it, preventing it from turning into dead stock that takes up valuable space and contributes to shrinkage. This strategic approach to inventory management, driven by ERP insights, not only prevents losses but also optimizes cash flow and profitability.

Combatting Vendor Fraud and Supply Chain Discrepancies

The supply chain, from manufacturing to delivery, involves multiple handoffs and opportunities for discrepancies, some of which can stem from vendor fraud. This might include suppliers short-shipping orders, invoicing for goods that were never delivered, or delivering goods of inferior quality that are not properly accounted for. Without a robust system to verify and reconcile incoming shipments against purchase orders and contracts, retailers are vulnerable to these subtle yet significant forms of loss. This is another critical area where ERP’s role in preventing shrinkage in retail inventory proves indispensable.

An ERP system provides a transparent and auditable framework for managing vendor relationships and tracking the entire procurement lifecycle. When a purchase order is created in the ERP, it contains detailed information about the items, quantities, agreed prices, and delivery terms. Upon receipt of goods, the ERP system facilitates a direct comparison between the physical delivery, the packing slip, and the original purchase order. Any discrepancies are immediately flagged, requiring investigation and resolution before the shipment is fully accepted and paid for. This automated reconciliation process makes it extremely difficult for vendors to short-ship or overcharge without detection. Moreover, the ERP can track vendor performance, identifying patterns of frequent discrepancies or quality issues, allowing retailers to make informed decisions about supplier relationships and negotiate better terms. This proactive vendor fraud prevention capability protects the retail business from losses originating outside its immediate control.

Enhanced Return Management and Fraud Prevention

Customer returns, while essential for good customer service, can also be a significant source of shrinkage if not managed effectively. Return fraud, where individuals attempt to return stolen merchandise, use fake receipts, or return items after using them extensively, is a growing concern for retailers. Manual or disconnected return processes make it easy for such fraudulent activities to go undetected. Here again, ERP’s role in preventing shrinkage in retail inventory offers powerful solutions by standardizing and centralizing the returns process.

When a return is processed through an ERP-integrated POS system, the system can instantly verify the original purchase, including the item, price, date, and payment method. It can flag suspicious patterns, such as an individual making frequent returns without corresponding purchases, returning high-value items without a receipt, or returning items that have been in the system for an unusually long time. The ERP can also enforce return policies automatically, preventing returns outside the eligible window or without proper documentation. Furthermore, once a returned item is accepted, the ERP immediately updates inventory records, ensuring that the stock count reflects the addition of the returned item, preventing “phantom returns” that mask actual missing inventory. By providing comprehensive data on every return, ERP systems empower retailers to identify and mitigate return fraud, turning a potential loss into an opportunity to restock and resell.

Leveraging Data Analytics and Reporting for Proactive Loss Prevention

Perhaps one of the most transformative aspects of ERP’s role in preventing shrinkage in retail inventory lies in its powerful data analytics and reporting capabilities. An ERP system collects vast amounts of data across all business functions, creating a rich repository of information about inventory movements, sales patterns, employee activities, and financial transactions. This data, when properly analyzed, can reveal insights and trends that are impossible to discern with fragmented systems.

ERP reporting tools can generate real-time dashboards and detailed reports on key performance indicators related to shrinkage. Retailers can track shrinkage by store location, product category, employee, or time of day, pinpointing specific vulnerabilities. For instance, reports might highlight a particular product category with consistently high shrinkage rates, prompting an investigation into whether it’s due to high theft risk, damaged goods, or administrative errors. Similarly, analytics can identify unusual transaction patterns at certain POS terminals or by specific employees, raising red flags for potential internal theft. By providing actionable insights, an ERP system shifts the approach to loss prevention from reactive investigation to proactive identification and mitigation of risks. This data-driven approach allows retailers to implement targeted loss prevention strategies, making their efforts more effective and efficient.

Integrating ERP with Other Loss Prevention Technologies

While ERP systems are powerful on their own, their effectiveness in ERP’s role in preventing shrinkage in retail inventory can be significantly enhanced when integrated with other specialized loss prevention technologies. These integrations create a synergistic ecosystem where data from various sources converges to provide an even more comprehensive and proactive approach to security and inventory control. This interconnectedness allows for a multi-layered defense against all forms of shrinkage.

Consider the integration of an ERP with CCTV systems: if unusual inventory discrepancies are detected via the ERP’s reports, security footage from the relevant area and time can be quickly pulled up for review. Integrating with Electronic Article Surveillance (EAS) systems means that alarms triggered at store exits can be cross-referenced with POS data via the ERP to verify if an item was paid for. RFID technology, when integrated with an ERP, offers unparalleled item-level tracking, allowing for real-time inventory counts and quick location of specific items, further reducing misplacement and theft. Even integration with access control systems can ensure that only authorized personnel can enter specific areas of a warehouse or backroom, with every entry and exit logged and auditable within the ERP. These integrations transform the ERP into the command center for a sophisticated retail security solution, consolidating information and enabling rapid response to potential threats.

Navigating the Challenges of ERP Implementation for Shrinkage Control

Despite the undeniable benefits, implementing an ERP system specifically to enhance ERP’s role in preventing shrinkage in retail inventory is not without its challenges. It’s a significant undertaking that requires careful planning, substantial investment, and a commitment to change management. One of the primary hurdles is the cost, which can be considerable, encompassing software licenses, customization, hardware, and ongoing maintenance. For many retailers, particularly small to medium-sized businesses, this initial outlay can seem daunting, yet the long-term ROI in shrinkage reduction often justifies the expense.

Another critical challenge is data migration. Moving vast amounts of existing inventory data, customer information, and financial records from disparate legacy systems into a new ERP requires meticulous planning and execution to ensure accuracy and prevent data loss. Furthermore, employee training is paramount. Even the most sophisticated ERP system is only as effective as the people using it. Resistance to change, lack of understanding, or improper usage can undermine the benefits. Comprehensive training programs are essential to ensure that all staff members, from warehouse personnel to sales associates and management, are proficient in using the new system and understand its importance in loss prevention. Addressing these challenges proactively through a well-defined implementation strategy is key to unlocking the full potential of an ERP system in combating retail shrinkage.

Choosing the Right ERP System for Your Retail Business

The market offers a diverse range of ERP solutions, and selecting the one that best enhances ERP’s role in preventing shrinkage in retail inventory for your specific business needs is a critical decision. Not all ERP systems are created equal, particularly when it comes to their suitability for the unique demands of the retail sector. Key factors to consider include scalability, industry-specific functionalities, integration capabilities, and the vendor’s reputation and support.

For retailers, an ERP system that offers strong modules for inventory management, POS integration, supply chain management, and robust reporting is paramount. Look for systems that are designed with retail nuances in mind, perhaps offering features like multi-channel inventory synchronization (for bricks-and-mortar and e-commerce), product attribute management, and flexible pricing capabilities. Cloud-based ERP solutions are increasingly popular due to their scalability, lower upfront infrastructure costs, and accessibility, making them an attractive option for growing retailers. Furthermore, evaluating the vendor’s track record, customer support, and their commitment to ongoing updates and security is crucial. A successful ERP implementation, particularly one focused on minimizing shrinkage, hinges not just on the software itself but also on the strength of the partnership with the chosen ERP provider. Conducting thorough due diligence and potentially engaging with consultants specialized in retail ERP implementations can significantly de-risk this crucial investment.

Measuring the ROI of ERP in Shrinkage Reduction

Implementing an ERP system is a significant investment, and understanding its return on investment (ROI), particularly in terms of ERP’s role in preventing shrinkage in retail inventory, is essential for justifying the expenditure and demonstrating its value. Quantifying the precise impact of ERP on shrinkage can be complex, as shrinkage itself is multifaceted, but a structured approach can reveal compelling results. The ROI isn’t just about direct cost savings; it also includes improved efficiency and enhanced decision-making capabilities.

To measure ROI, retailers should establish baseline shrinkage rates before ERP implementation. This can be done by calculating the percentage difference between recorded inventory and physical inventory value over a specific period. After implementation, ongoing monitoring of this metric will show the direct impact of the ERP. Furthermore, track improvements in related areas: reductions in administrative errors, fewer stockouts (leading to fewer lost sales), improved inventory turnover, and a decrease in discrepancies during receiving. The ERP’s reporting features can facilitate this tracking. Beyond direct financial savings from reduced losses, consider the qualitative benefits: improved employee morale due to streamlined processes, enhanced customer satisfaction from accurate stock availability, and the ability to make data-driven strategic decisions. Over time, the cumulative savings from preventing various forms of shrinkage, coupled with gains in efficiency, will typically far outweigh the initial investment, making a compelling case for the ERP as a crucial tool for profitability.

Future Trends: AI, IoT, and Blockchain in ERP for Loss Prevention

The landscape of retail is constantly evolving, and so too are the technologies that underpin ERP systems and ERP’s role in preventing shrinkage in retail inventory. Emerging technologies like Artificial Intelligence (AI), Internet of Things (IoT), and Blockchain are set to further revolutionize loss prevention, offering even more sophisticated ways to combat shrinkage. Integrating these innovations with future ERP platforms will unlock unprecedented levels of visibility, predictive capabilities, and security.

AI, for instance, can analyze vast datasets from the ERP to identify subtle patterns indicative of shrinkage that human analysts might miss. AI algorithms can detect anomalies in sales data, inventory adjustments, or employee behavior, flagging potential fraud or errors in real-time. IoT devices, such as smart shelves or environmental sensors, can provide continuous, real-time updates on inventory levels, location, and condition, directly feeding this granular data into the ERP. This level of physical-world data integration will make inventory accuracy near-perfect and immediately highlight missing items. Blockchain technology offers a decentralized, immutable ledger that can record every transaction and movement of goods across the supply chain, from manufacturer to consumer. This transparent and tamper-proof record could eliminate vendor fraud, verify product authenticity, and provide irrefutable evidence in shrinkage investigations. As ERP systems continue to evolve, their integration with these cutting-edge technologies will make them even more potent weapons in the ongoing battle against retail shrinkage, securing the profitability of retailers well into the future.

Conclusion: Reinforcing ERP’s Indispensable Role in Retail Inventory Security

In the dynamic and often challenging world of retail, where profit margins can be razor-thin, the silent drain of shrinkage poses a continuous threat. From external theft and internal fraud to administrative errors and supply chain discrepancies, the avenues for loss are numerous and pervasive. Yet, as this comprehensive exploration has demonstrated, retailers are not powerless against this foe. A robust Enterprise Resource Planning (ERP) system emerges as an indispensable tool, playing a multifaceted and critically important role in safeguarding retail inventory and preventing shrinkage across the entire operation.

ERP’s role in preventing shrinkage in retail inventory is foundational because it provides the central nervous system for a retail business. By integrating every function – from procurement and warehousing to sales and finance – into a single, unified system, ERP eliminates data silos and fosters unprecedented real-time visibility and accuracy. This integration enables enhanced inventory accuracy through automated tracking, minimizes errors in receiving and stock movement, and fortifies the point of sale against discrepancies and fraud. It empowers retailers with strong audit trails and access controls to deter internal theft, while sophisticated data analytics illuminate patterns of loss for proactive intervention. Furthermore, ERP strengthens supply chain integrity, optimizes inventory planning to reduce obsolescence, and streamlines return management to combat fraud. As retail continues to evolve, with the advent of AI, IoT, and Blockchain, ERP systems are poised to become even more potent, offering predictive insights and immutable records to further secure retail assets. Investing in a comprehensive ERP solution is no longer merely an option for retailers; it is a strategic imperative for not just mitigating shrinkage, but for ensuring long-term profitability, operational efficiency, and a truly secure inventory ecosystem.