Embarking on a journey to modernize your manufacturing operations can feel daunting, especially when faced with the myriad of technology solutions available today. For small manufacturing businesses, the decision to upgrade from fragmented legacy systems or even manual processes to a unified, intelligent platform is not just about efficiency; it’s about survival and growth in a highly competitive global market. This comprehensive guide, Transitioning to Cloud ERP for Small Manufacturing: A Roadmap, will illuminate the path, helping you navigate the complexities and unlock the transformative power of a cloud-based Enterprise Resource Planning (ERP) system tailored for your unique needs. We’ll explore why now is the time, what to expect, and how to execute a successful transition, ensuring your small manufacturing enterprise is future-ready.

The Imperative: Why Small Manufacturers Need Cloud ERP Now More Than Ever

In the past, Enterprise Resource Planning (ERP) systems were often perceived as monolithic, expensive solutions primarily accessible to large corporations. This perception, however, is rapidly becoming outdated, particularly with the advent of cloud technology. Small manufacturing businesses are now operating in an environment characterized by fluctuating demand, intricate supply chains, and an ever-increasing need for real-time data to make agile decisions. Relying on spreadsheets, disconnected software, or even paper-based records simply isn’t sustainable when your competitors are leveraging integrated systems to optimize every facet of their operations.

The shift towards cloud-based solutions has democratized access to powerful ERP capabilities, making them not only affordable but also highly scalable and user-friendly for smaller organizations. Cloud ERP for small manufacturing provides the tools necessary to centralize crucial business functions – from production planning and inventory management to financial accounting and customer relationship management – into a single, cohesive platform. This integration eliminates data silos, reduces manual errors, and provides a holistic view of your business, which is an absolute game-changer for companies striving for efficiency and growth without the extensive IT overhead typically associated with on-premise solutions. Without this unified approach, small manufacturers often struggle with inventory discrepancies, production delays, and a lack of clear financial oversight, all of which directly impact profitability and customer satisfaction.

Unpacking the Benefits: Advantages of Cloud ERP for Small Manufacturing

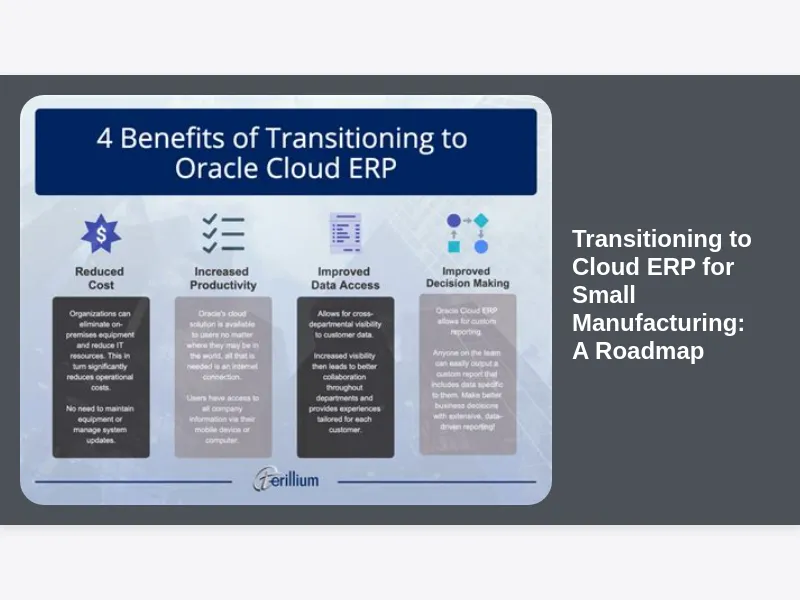

The decision to embark on Transitioning to Cloud ERP for Small Manufacturing: A Roadmap is fundamentally driven by the extensive benefits it offers, particularly in contrast to traditional on-premise systems or piecemeal software solutions. One of the most significant advantages is the considerable reduction in upfront capital expenditure. With cloud ERP, you’re typically looking at a subscription model, meaning lower initial costs and predictable monthly or annual fees, which is a huge boon for small businesses with tighter budgets. This model transforms what would once be a large capital investment into an operational expense, freeing up capital for other critical areas of your manufacturing business, such as R&D or marketing.

Beyond cost savings, the scalability and flexibility of cloud ERP are unparalleled. As your small manufacturing business grows, your ERP system can easily scale with you, accommodating increased users, more complex operations, or additional modules without requiring major hardware upgrades or lengthy implementation cycles. This inherent agility allows you to adapt quickly to market changes, expand into new product lines, or take on larger orders without being hampered by your IT infrastructure. Furthermore, cloud-based solutions offer superior accessibility; your team can access critical data and functions from anywhere, at any time, on any device with an internet connection. This is particularly valuable for remote teams, traveling sales staff, or management needing to check on operations outside of the traditional office setting, fostering better collaboration and faster decision-making across your entire organization.

Laying the Foundation: Understanding Your Current State of Operations

Before you can effectively embark on Transitioning to Cloud ERP for Small Manufacturing: A Roadmap, the absolute first step is to thoroughly understand your existing operational landscape. This isn’t just about identifying problems; it’s about gaining a granular understanding of every process, every data flow, and every bottleneck that currently exists within your small manufacturing business. Begin by documenting your current workflows from end-to-end: how orders are received, how raw materials are procured, how production is scheduled, how inventory is tracked, how products are shipped, and how financial transactions are managed. Don’t overlook the “hidden” processes or the workarounds that your team has developed over time; these often reveal critical areas of inefficiency or points of friction.

This comprehensive assessment should also include an inventory of your current software applications, spreadsheets, and manual systems. Identify which departments use which tools, how data is shared (or not shared) between them, and where data entry is duplicated. Understanding the current state isn’t about shaming existing methods; it’s about establishing a clear baseline against which you can measure future improvements and identify the specific pain points that a new Cloud ERP system needs to address. For instance, if your current inventory system consistently leads to stockouts or overstocking, that becomes a key requirement for your new solution. A clear understanding of your current limitations will be invaluable when defining your requirements and selecting the right cloud ERP platform for your manufacturing operations.

Blueprinting Success: Defining Your Needs and Strategic Goals for ERP

Once you have a clear picture of your current operational state, the next crucial step in your Transitioning to Cloud ERP for Small Manufacturing: A Roadmap is to precisely define your needs and strategic goals. This phase moves beyond merely identifying problems to articulating what a successful Cloud ERP implementation would look like for your specific manufacturing business. Start by categorizing your needs: What are the absolute “must-haves” for a new system? These might include robust production scheduling, real-time inventory tracking, integrated financial reporting, or comprehensive quality control features. Then, consider your “nice-to-haves” – features that would be beneficial but aren’t critical for initial success.

More importantly, connect these needs to your broader strategic objectives. Are you aiming to reduce production lead times by 15%? Do you want to improve on-time delivery rates to 98%? Is your goal to gain better visibility into your profit margins per product line? By linking your ERP requirements directly to measurable business outcomes, you create a clear vision for success and establish key performance indicators (KPIs) against which you can evaluate the ERP’s effectiveness post-implementation. This strategic alignment ensures that your Cloud ERP system isn’t just a piece of software, but a powerful tool driving your small manufacturing business toward its long-term goals, such as enhanced competitiveness, increased profitability, and sustainable growth.

Exploring the Landscape: Researching Cloud ERP Solutions for Small Manufacturing

With your needs and strategic goals clearly defined, you’re ready to dive into the market and begin researching Cloud ERP solutions specifically designed for small manufacturing businesses. This isn’t a one-size-fits-all market; different vendors offer varying strengths, industry specializations, and pricing models. Begin by identifying leading Cloud ERP providers that cater to the manufacturing sector, paying particular attention to those with a strong track record supporting businesses of your size and complexity. Look for solutions that offer core modules essential for manufacturing, such as production planning, material requirements planning (MRP), shop floor control, inventory management, and quality assurance, alongside standard financial and CRM capabilities.

Beyond features, delve into the vendor’s reputation, customer support, and their long-term vision. Read reviews, seek out case studies, and if possible, speak with other small manufacturers who have implemented similar solutions. Pay close attention to the flexibility of the system – can it be configured to match your unique manufacturing processes without extensive, costly customizations? Evaluate their integration capabilities with other tools you might already use, such as CAD software or e-commerce platforms. This thorough research phase is critical for shortlisting potential vendors and understanding the breadth of options available, ensuring you choose a Cloud ERP solution that aligns perfectly with the roadmap you’ve designed for your small manufacturing enterprise.

Assembling Your A-Team: Building Your Cloud ERP Implementation Crew

A successful Transitioning to Cloud ERP for Small Manufacturing: A Roadmap hinges not just on the software itself, but critically on the people driving its adoption. For small manufacturers, assembling the right internal implementation team is paramount, even if the team is lean. This isn’t solely an IT project; it’s a business transformation project that requires representation from across your organization. At a minimum, your team should include a project leader – someone with strong organizational skills and a good understanding of your company’s overall operations. This individual will be the central point of contact, ensuring communication flows smoothly and decisions are made efficiently.

Beyond the project leader, include key stakeholders from various departments that will be impacted by the ERP system. This typically means representatives from production, inventory, finance, sales, and potentially even quality control. These individuals bring invaluable domain expertise, ensuring that the system is configured to meet the specific needs of their respective areas and facilitating user adoption later on. Their involvement also fosters a sense of ownership and reduces resistance to change. While you’ll likely work closely with your chosen ERP vendor’s implementation specialists, your internal team’s engagement, commitment, and active participation are the bedrock upon which a truly successful Cloud ERP deployment for your small manufacturing business will be built.

Migrating Your Intelligence: Data Migration Strategies for Cloud ERP

Data is the lifeblood of any manufacturing operation, and the process of migrating it from your old systems to your new Cloud ERP is one of the most critical and often underestimated phases in Transitioning to Cloud ERP for Small Manufacturing: A Roadmap. This isn’t merely about copying files; it’s about meticulously transferring, cleaning, and validating vast amounts of historical and current information to ensure the new system operates on accurate, reliable data from day one. Start by identifying all data sources that need to be migrated, which typically include customer records, vendor information, product data (BOMs, routings), inventory levels, historical sales orders, open purchase orders, and financial balances.

Before migration, a comprehensive data cleansing effort is absolutely essential. This involves identifying and rectifying errors, removing duplicate entries, standardizing formats, and archiving outdated or irrelevant information. Migrating “dirty” data into a new ERP system will only perpetuate existing problems and undermine the benefits you expect to gain. Develop a clear data mapping plan that shows exactly where each piece of information from your old system will reside in the new Cloud ERP. Work closely with your chosen vendor or an experienced data migration specialist to utilize appropriate tools and methodologies, such as incremental migrations or phased rollouts, to minimize disruption to your ongoing manufacturing operations. A well-executed data migration ensures that your new ERP system is built on a solid foundation of accurate and trustworthy information, empowering informed decision-making across your entire small manufacturing enterprise.

Refine and Optimize: Process Mapping and Re-engineering with Cloud ERP

The implementation of a Cloud ERP system presents a unique opportunity not just to automate existing processes, but to fundamentally improve and optimize them. This phase of Transitioning to Cloud ERP for Small Manufacturing: A Roadmap involves a thorough process mapping exercise, where you diagram your current “as-is” workflows and then design your ideal “to-be” processes, leveraging the capabilities of your new ERP. Don’t simply replicate inefficient manual steps within the new system; instead, challenge every step and ask how the ERP can enable a more streamlined, effective, and intelligent way of working.

For a small manufacturing business, this could mean re-evaluating how sales orders are processed, how production is scheduled to minimize changeovers, how inventory is replenished to reduce carrying costs, or how quality checks are integrated directly into the production flow. The goal is to identify opportunities for automation, eliminate redundant steps, improve communication between departments, and enhance data accuracy. This re-engineering effort, often facilitated by workshops with your implementation team and the ERP vendor’s experts, ensures that you’re not just installing software but truly transforming your operations. A well-designed “to-be” process, optimized for your Cloud ERP, will maximize the return on your investment, leading to significant gains in efficiency, reduced operational costs, and improved overall productivity for your manufacturing business.

Making the Right Choice: Vendor Selection for Your Cloud ERP Partner

Choosing the right Cloud ERP vendor is perhaps one of the most critical decisions in your Transitioning to Cloud ERP for Small Manufacturing: A Roadmap. This isn’t just a software purchase; it’s a long-term partnership that will significantly impact your manufacturing business’s future. After your initial research and shortlisting, engage in a rigorous evaluation process. Request detailed demonstrations of the shortlisted solutions, ensuring the demos are tailored to your specific manufacturing processes and highlight how the ERP addresses your defined needs and pain points. Provide the vendors with realistic scenarios from your operations, such as a complex production order or a specific inventory challenge, and ask them to demonstrate how their system handles it.

Beyond the software itself, thoroughly vet the vendor’s experience, reputation, and commitment to customer success. Inquire about their implementation methodology, their support structure post-go-live, and their track record with small manufacturing clients. Request references and actually speak with them to gather firsthand insights into their experience working with the vendor. Pay close attention to pricing models, including all hidden costs such as data migration, training, or additional modules you might need in the future. A transparent and trustworthy vendor that truly understands the nuances of small manufacturing and offers dedicated support will be an invaluable partner throughout your Cloud ERP journey, ensuring a smoother transition and maximizing the long-term value of your investment.

Tailoring the Fit: Customization vs. Configuration in Cloud ERP

As you progress in your Transitioning to Cloud ERP for Small Manufacturing: A Roadmap, a key discussion point with your chosen vendor will revolve around customization versus configuration. It’s a common misconception that ERP systems must be heavily customized to fit unique business processes. However, modern Cloud ERP solutions are designed with extensive configuration options, allowing you to tailor the system to your specific requirements without altering the core code. Configuration involves adjusting settings, defining workflows, creating custom fields, and setting up reports within the existing framework of the software. This approach is generally preferred because it keeps your system closer to the standard vendor release, making upgrades and maintenance much simpler and less costly in the long run.

Customization, on the other hand, involves modifying the underlying source code of the ERP system to add new functionality or drastically change existing ones. While sometimes necessary for highly specialized manufacturing processes, extensive customization carries significant risks for small manufacturers. It can lead to higher implementation costs, make future upgrades complex and expensive (often referred to as “version lock”), and increase the potential for bugs or integration issues. Always strive for configuration first, and only consider customization as a last resort for truly unique and mission-critical requirements that cannot be met otherwise. Your vendor should guide you in finding the right balance, ensuring your Cloud ERP meets your needs effectively while maintaining the agility and upgradeability inherent in cloud solutions.

Empowering Your Team: Training and Change Management for ERP Adoption

Implementing a new Cloud ERP system is as much about people as it is about technology. A crucial phase in Transitioning to Cloud ERP for Small Manufacturing: A Roadmap is robust training and comprehensive change management. Even the most perfectly designed system will fail if your team doesn’t understand how to use it or resists its adoption. Start developing a clear communication plan early in the process, explaining why the ERP is being implemented, what benefits it will bring to individuals and the company, and how it will improve their daily work. Address concerns openly and foster an environment where employees feel heard and supported.

Training should be multi-faceted and tailored to different user groups within your small manufacturing business. Operators on the shop floor will need different training than finance personnel or sales staff. Provide hands-on sessions, user manuals, and accessible resources for ongoing support. Consider “super users” within each department who can become internal experts and first-line support for their colleagues. Change management isn’t a one-time event; it’s an ongoing process of support, reinforcement, and feedback. By investing adequately in training and proactively managing the human element of change, you empower your employees to embrace the new Cloud ERP system, ensuring a smoother transition and ultimately maximizing its potential to drive efficiency and productivity throughout your manufacturing operations.

The Moment of Truth: The Implementation Phase and Go-Live Strategy

After meticulous planning, data migration, process re-engineering, and training, you reach the pivotal implementation phase and the much-anticipated “go-live.” This is when your small manufacturing business officially begins operating on the new Cloud ERP system. A well-defined go-live strategy is essential to minimize disruption and ensure a smooth transition. Consider a phased approach, where different modules or departments go live sequentially, rather than a “big bang” approach where everything switches over at once. For instance, you might first go live with inventory and procurement, then move to production planning, and finally integrate finance, allowing your team to adapt gradually.

During the go-live period, having extra support on hand is critical. This includes your internal super users, your core implementation team, and definitely your ERP vendor’s support staff. Be prepared for a temporary dip in productivity as employees adjust to new workflows and the system itself. Maintain open communication channels for users to report issues and ask questions, and ensure a rapid response system is in place for troubleshooting. Thorough testing prior to go-live, including user acceptance testing (UAT), will significantly mitigate risks. While challenges may arise, a strategic and supported go-live ensures that your Transitioning to Cloud ERP for Small Manufacturing: A Roadmap culminates in a successful launch, setting your business on a trajectory of enhanced efficiency and control.

Beyond Launch: Post-Implementation Support and Continuous Optimization

Going live with your Cloud ERP system is a significant milestone, but it’s not the end of your Transitioning to Cloud ERP for Small Manufacturing: A Roadmap journey; it’s just the beginning of a continuous process of support and optimization. Immediately after go-live, prioritize robust post-implementation support. This means ensuring your internal team has access to help desks, knowledge bases, and direct contact with your ERP vendor for any issues that arise. The initial weeks and months will involve a learning curve, and prompt resolution of problems is crucial for user confidence and sustained adoption. Establish regular check-ins with department heads to gather feedback and identify areas where users might still be struggling.

Furthermore, a Cloud ERP system is not a static tool; it’s a dynamic platform that can evolve with your small manufacturing business. Dedicate resources to ongoing optimization. This involves periodically reviewing your processes within the ERP, identifying opportunities for further automation, refining reports for better insights, or even exploring additional modules as your business needs grow. The data generated by your ERP offers a wealth of information that can be analyzed to identify trends, improve forecasting, and make more informed strategic decisions. Continuous training for new hires and refresher courses for existing staff will also ensure the system’s capabilities are fully leveraged, solidifying the long-term value and ROI of your Cloud ERP investment.

Proving the Value: Measuring Success with KPIs for Cloud ERP

How do you truly know if your Transitioning to Cloud ERP for Small Manufacturing: A Roadmap has been a success? The answer lies in establishing and continuously monitoring key performance indicators (KPIs) that are directly linked to your initial strategic goals. Before implementation, you defined what success would look like; now it’s time to measure it. For a small manufacturing business, relevant KPIs might include a reduction in inventory holding costs, an improvement in on-time delivery rates, a decrease in production lead times, an increase in production output per employee, or a reduction in manual data entry errors.

Financial KPIs are also critical, such as improved cash flow, increased profit margins, and a faster month-end close process. The beauty of a well-implemented Cloud ERP system is its ability to centralize data and provide real-time reporting, making it far easier to track these metrics. Schedule regular reviews – monthly or quarterly – to analyze these KPIs and compare them against your pre-ERP benchmarks. This data-driven approach not only validates your investment but also highlights areas where further optimization might be needed. By consistently measuring success, you ensure that your Cloud ERP system remains a powerful driver of efficiency, profitability, and continuous improvement for your small manufacturing operations.

Growing Pains Solved: Scaling Your Small Manufacturing Business with Cloud ERP

One of the most compelling reasons for Transitioning to Cloud ERP for Small Manufacturing: A Roadmap is the inherent scalability it offers, which is crucial for businesses aiming for growth. As your small manufacturing enterprise expands – whether by increasing production volume, adding new product lines, acquiring other companies, or entering new markets – your Cloud ERP system is designed to scale with you, minimizing the need for disruptive overhauls. Unlike on-premise systems that often require significant hardware upgrades and extensive reconfigurations to handle increased loads, cloud solutions can typically accommodate growth by simply adjusting your subscription plan or adding new modules.

This agility means that your ERP infrastructure won’t become a bottleneck as you pursue ambitious growth strategies. For instance, if you decide to implement lean manufacturing principles or integrate advanced automation on the shop floor, many Cloud ERPs offer modules or integration capabilities to support these initiatives. The ability to easily add more users, expand data storage, or incorporate sophisticated functionalities like advanced planning and scheduling (APS) or quality management (QMS) ensures that your technology platform evolves alongside your business needs. With Cloud ERP, small manufacturers can confidently plan for expansion, knowing their core operational system is ready to support and facilitate that growth without incurring prohibitive costs or complex IT challenges.

Addressing the Elephants in the Room: Security and Downtime Concerns in Cloud ERP

For many small manufacturing businesses considering Transitioning to Cloud ERP for Small Manufacturing: A Roadmap, concerns around data security and system downtime are often at the forefront. It’s natural to feel apprehension about entrusting critical business data to a third-party cloud provider. However, it’s important to understand that reputable Cloud ERP vendors invest heavily in robust security measures that often far exceed what a small manufacturing company could implement on its own. These measures include advanced encryption, multi-factor authentication, regular security audits, disaster recovery protocols, and redundant data centers to protect your sensitive information from cyber threats and physical damage.

Regarding downtime, cloud providers typically offer impressive uptime guarantees, often 99.9% or higher, meaning very minimal interruptions. Their infrastructure is designed for high availability and resilience, with failover systems in place to ensure continuous operation. In contrast, on-premise systems are vulnerable to local power outages, hardware failures, or IT staff limitations that can lead to significant and often unpredictable downtime. While no system is immune to all issues, choosing a reputable Cloud ERP vendor with a strong security posture and proven uptime record effectively transfers much of the burden and risk of IT infrastructure management from your shoulders to theirs, allowing you to focus on your core manufacturing operations rather than worrying about data integrity or system availability.

Crunching the Numbers: Cost Considerations and ROI of Cloud ERP

Understanding the financial implications is paramount when contemplating Transitioning to Cloud ERP for Small Manufacturing: A Roadmap. While cloud ERP often boasts lower upfront costs compared to traditional on-premise systems, it’s crucial to analyze the total cost of ownership (TCO) over a multi-year period. Beyond the recurring subscription fees, factors to consider include the costs associated with initial implementation (consulting, data migration, configuration), any necessary third-party integrations, ongoing support and maintenance, and potential training expenses. It’s wise to get a detailed breakdown from potential vendors to avoid surprises and ensure all cost elements are factored into your budget planning.

However, the expenditure on Cloud ERP should not be viewed merely as a cost, but as an investment with a clear return. The return on investment (ROI) for a small manufacturing business can be substantial and multifaceted. This includes tangible benefits like reduced operational costs through increased efficiency, optimized inventory management leading to lower carrying costs and fewer stockouts, and improved accuracy in financial reporting. Intangible benefits, though harder to quantify, are equally significant: better decision-making capabilities due to real-time data, enhanced customer satisfaction through improved order fulfillment, increased employee productivity, and the strategic advantage of agility and scalability. By carefully weighing the TCO against the potential for efficiency gains, cost savings, and business growth, you can build a compelling business case for your Cloud ERP investment. [Link to a Gartner or Forrester report on ERP ROI studies]

Envisioning the Future: The Evolving Landscape of Manufacturing with Cloud ERP

The journey of Transitioning to Cloud ERP for Small Manufacturing: A Roadmap is also a leap into the future of manufacturing. Cloud ERP is not just about digitizing current processes; it’s a foundational technology that enables small manufacturers to embrace emerging trends and technologies, ensuring they remain competitive and innovative. Think about the rise of Industry 4.0 – the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML). A cloud-based ERP system serves as the central nervous system, capable of integrating with IoT sensors on your shop floor to collect real-time data on machine performance, predictive maintenance, and production output.

This integration allows for advanced analytics and AI-driven insights, which can optimize everything from production scheduling and quality control to demand forecasting and supply chain management. For instance, an ERP might use ML algorithms to predict equipment failure before it happens, minimizing costly downtime. It can also integrate with CAD/CAM systems, CRM tools, and e-commerce platforms, creating a truly connected enterprise. As technology continues to evolve, your Cloud ERP acts as an adaptable platform that can incorporate these innovations, giving your small manufacturing business the tools to continuously improve, innovate, and thrive in an increasingly digital and interconnected industrial landscape.

Illustrative Success: A Hypothetical Case Study of Cloud ERP in Action

To further solidify the concepts within this Transitioning to Cloud ERP for Small Manufacturing: A Roadmap, let’s consider a hypothetical example. Imagine “Precision Parts Inc.,” a small manufacturing company specializing in custom metal components. Before Cloud ERP, Precision Parts struggled with fragmented data: sales orders were managed in one system, production schedules on spreadsheets, inventory manually counted, and financials in an outdated accounting package. This led to frequent production delays, inaccurate inventory counts causing missed customer commitments, and a lack of real-time visibility into their true costs per job. Their growth was stagnating due to these inefficiencies.

Precision Parts embarked on their Cloud ERP transition, carefully following the steps outlined in this roadmap. They defined their needs, selected a manufacturing-specific Cloud ERP solution, migrated clean data, and re-engineered their production and inventory processes. After a phased go-live and comprehensive training, the results were transformative. Inventory accuracy jumped from 70% to 98%, reducing carrying costs by 15% and eliminating costly expedited orders. Production lead times decreased by 20% due to better scheduling and real-time shop floor visibility. Financial reporting became instantaneous, allowing management to make proactive decisions based on accurate profit margins per product line. This Transitioning to Cloud ERP for Small Manufacturing: A Roadmap enabled Precision Parts Inc. to not only overcome their inefficiencies but also to secure larger contracts and expand their market share, proving the tangible value of a well-executed Cloud ERP implementation.

The Road Ahead: Why Starting Your Cloud ERP Journey Today is Crucial

The decision to embark on Transitioning to Cloud ERP for Small Manufacturing: A Roadmap is more than just an IT project; it is a strategic imperative for any small manufacturing business looking to thrive in the modern economy. The challenges of maintaining competitiveness, managing complex supply chains, and meeting evolving customer demands are simply too great to be handled by outdated or disparate systems. Cloud ERP offers a powerful, scalable, and cost-effective solution that centralizes your operations, provides real-time insights, and significantly enhances your business agility.

While the journey may seem complex, by following a structured roadmap – from understanding your current state to post-implementation optimization – you can navigate the transition successfully. The benefits of improved efficiency, reduced operational costs, enhanced decision-making, and the ability to scale your business are not just aspirational; they are achievable realities that will position your small manufacturing enterprise for sustained growth and profitability. Don’t let the fear of change hold you back. The time to modernize your operations and unlock your full potential is now. Embrace the future of manufacturing by taking the decisive step towards a Cloud ERP system tailored for your success.